الحار منتجات

ملكنا الإخبارية

clinker and gypsum grinding mills

Energy and exergy analyses for a cement ball mill of a

202021 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement. In this work, the energy and exergy analyses of a cement

(PDF) Effects of Mill Speed and Air Classifier Speed on

2021629 PDF Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as

Review on vertical roller mill in cement industryits

202111 Extracted cooled clinker and other additives like gypsum, fly ash etc. are fed to the cement mill in a controlled manner in specific quantity. The cement mill is either a

Quantifying the effect of clinker grinding aids under laboratory

2015101 The effect of clinker grinding aids (GAs) on mill performance and cement properties is currently quantified in real-scale grinding plants. In fact, laboratory-grinding

An industrial comparative study of cement clinker grinding

201251 This stone presents an investigation carried out to compare the three clinker grinding systems, namely, the combined grinding (Comflex®) circuit, HPRM-only circuit,

Analysis of material flow and consumption in cement

2016120 Waste gas recycling rate in clinker production is higher than in other stages. • Recycling waste gas discharged from raw and cement mills should be the

Industrial versus Laboratory Clinker Processing Using Grinding

2015914 A measured fresh feed mixture (B0) of precrushed clinker, gypsum, and pozzolan is introduced in the mill. After grinding, an elevator conveys the entire ground

An industrial comparative study of cement clinker grinding

201251 Comparing industrial clinker grinding for three different grinding systems. Energy consumption and cement quality variations at the same cement fineness. The

(PDF) Optimization of Gypsum Composition Against Setting

202121 clinker grinding process does control by the content of sulfur trioxide (SO 3) in the cement produced. The higher SO 3 content in cement indicates that the gypsum

Minerals Free Full-Text The Challenge of Grinding Ternary

2022916 Two main target products will be discussed: (i) LC3, a binder with a formulation of 50% clinker, 30% calcined clay, 15% limestone and 5% gypsum, co

Review on vertical roller mill in cement industryits

202111 Extracted cooled clinker and other additives like gypsum, fly ash etc. are fed to the cement mill in a controlled manner in specific quantity. The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from minimum 50 TPH while larger installations are up to 450 TPH [8].

Analysis of high clinker ratio of Portland Composite Cement (PCC)

2020101 The clinker was mixed with gypsum and pozzolanic material to produce PCC cement. Plant closed-circuit tube mill used for producing PCC is schematically presented in Fig. 2. Pre-crushed clinker from clinker bin is filled to the hoper feeder before introduced to pre-grinder.

CLINKER GRINDING IN CEMENT PRODUCTION

2019221 Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules

Differential comminution of gypsum in cements ground in different mills

200371 Identical mixes containing fixed amounts of ordinary Portland cement clinker and gypsum were ground in two types of industrial cement mills—viz. ball mill (BM) and vertical roller mill (VRM)—to identical Blaine fineness to examine the effect of any possible differential comminution of gypsum on cement setting times. The present investigation

Loesche Mills for Cement and Granulated Blast Furnace

2017811 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche. The first use of a Loesche mill, with a grinding track diameter of only 1.1 metres, was used as long ago as 1935. However, the breakthrough in grinding this type of material on the vertical

What Is Cement Milling? Difference Between Raw Mill And Cement Mill

2019129 Cement milling is the process of grinding together cement clinker, gypsum and other additives to produce a fine grey powder. The resulting material, called “cement meal”, is then heated in a rotary kiln to around 2,000°F to produce the finished product known as Portland cement, which can be used for many different construction purposes.

Portland Cement Clinker an overview ScienceDirect Topics

Coal utilisation in the cement and concrete industries. G. Schumacher, L. Juniper, in The Coal Handbook: Towards Cleaner Production: Coal Utilisation, 2013 15.3.1 Make-up of Portland cement. Portland cement is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of gypsum (calcium sulphate dehydrate

Cement Extraction, Processing, Manufacturing Britannica

The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. The material may pass straight through the mill (open-circuit grinding), or coarser material may be separated from the ground product and returned to the mill for further grinding (closed-circuit

Cement Grinding Plant Overview Cement Grinding Unit

20191011 The whole workflow of the cement grinding plant is as follows: the cement clinker, gypsum, and mixture in the cement silo are mixed by the belt conveyor in a certain proportion and transported to the cement roller press, cement mill or group of them for grinding. The cement is ground by the cement mill to the required particle size.

Energy-Efficient Technologies in Cement Grinding

2016105 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Everything you need to know about clinker/cement Grinding

Or, there are 3 bins, but they are designed for clinker or gypsum and not the mineral component. helps the dispersal of grinding aid in mill), at approximately 2-2.5 Lb./Ton for medium fineness and 3-4 Lb./Ton for high fineness cement. (Check with your supplier). Willi Suter Presentation Price. 1300 2000 $/t. Dosage rate 200-400 g/t. 0.

Addition Of Gypsum In Grindid Clinker Crusher Mills, Cone

Clinker Grinding Mills for Cement Production at Ghana Clinker and gypsum are imported whilst limestone is obtained locally. In addition, their capacity and Figure 1 presents the design of the clinker grinding system

CLINKER GRINDING UNIT PROCESS ENGINEERING

20231027 Clinker and gypsum, being mixed together in predetermined proportions, are fed to the grinding mills. Chemical gypsum, if used instead of natural gypsum, needs to be dried either by natural sun drying or by mechanical drying, before it is used with cooled and dried clinker for inter grinding in mills.

A Review on Pyroprocessing Techniques for Selected Wastes

202029 The grinding elements and mill settings are modified to grind harder materials such as clinker and granulated blast-furnace slag. Power use is between 26 and 29 kWh/t when grinding to a Blaine area 3,300 cm 2 /g using a VRM [ 28 ].

(PDF) Mining Activities, Cement Production Process and

202274 Inside the mill there a re iron balls grinding media with sizes of 40, 50, 60, 70, 80 and 90mm. The grinded powder is sucked to the separator for classification.

11.6 Portland Cement Manufacturing U.S.

20211110 Either gypsum or natural anhydrite, both of which are forms of calcium sulfate, is introduced to K. Clinker transfer -16 L. Clinker grinding -17 M. Cement silos -18 N. Cement load out -19 R. Finish grinding mill feed belt -27 S. Finish grinding mill weight hopper -28 T. Finish grinding mill air seperator -29 U. Preheater kiln 3-05-006

كسارة الفك للبيع في ولاية مينيسوتا

اسعار طاحونة لقمح

بيع مواد البناء الأسطوانة محطم للبيع

Pt Kai التعدين جاكرتا

ذخیره سازی پره های چرخ

تفاصيل مجسمات 2014 كسارة الفك

E Penses من أعمال المحاجر ذات الصلة

أزياء من الكسارات الذرة القديم تأثير

مطحنة طحن مسحوق الزنك الخام

تهتز الرقص خام الذهب

كسارات الفك البريطانية الصنع

ماكينات استخراج الرمال طوف

جوانب السلامة في صناعة تعدين الفحم في اندونيسيا

mining gold plant flow diagram

محطة كسارة الحجر المحمول في التعدين في روسيا

شاشات mogensen على رمل السيليكا التعدين orecrusher

كسارات الحجر للبيع إيطاليا

كسارة مخروطية متنقلة من الدولوميت في ماليزيا

أنواع مختلفة من كسارة حجر الفك charte

طحن الفحم وتحويله إلى مسحوق في محطة توليد الكهرباء في فيتنام

الجينسنغ الكورية استخراج قرن الوعل سعر كبسولة لينة

بدلا من الأسمنت الرملي

تكلفة مصنع كسارة البازلت

تطبيقات كسارة gyratory الكسارة التكنولوجيا المحدودة

المحمولة مصنع معالجة خام

الناصر لتاجير معدات البناء

حول لدينا

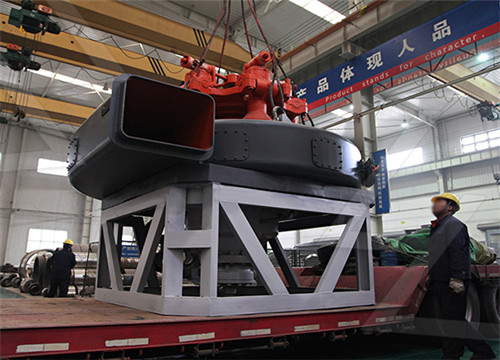

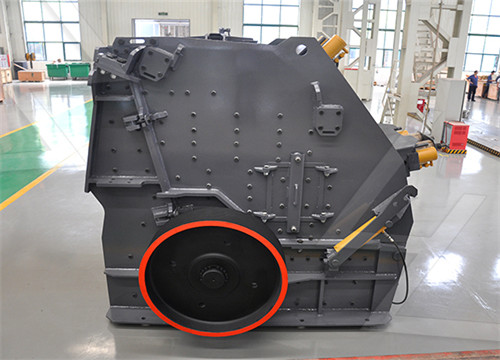

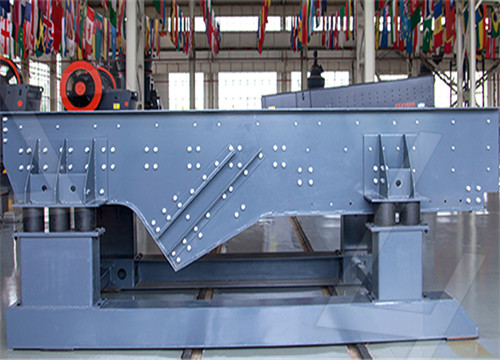

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20