الحار منتجات

ملكنا الإخبارية

screening without blocking one crusher

CRUSHING SCREENING Crushing and Screening

2017530 sure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There are also primary and secondary types of these crushers. Jaw

The screening process: a vital component of the crushing

2022120 "There are two ways of looking at it: there's screening prior to crushing, and then screening after crushing. We want to make sure that we've got the whole

Crushing and Screening Handbook AusIMM

2021624 from site to site on standard trailers. This is one example of how our worldwide process know-how can serve your crushing, screening and conveying needs.

en/screening without blocking crusher.md at main

. Contribute to sbmboy/en development by creating an account on GitHub.

Measurement-Control for Crushing and Screening Process

202363 Measurement for Crushing and Screening Process. It mainly includes the measurement for the material level of ore bin, solid material flow, the state of belt

Guidelines for Management Crushing and Screening

201835 MinEx Guideline Crushing and Screening Page 4 of 10 © MinEx 2009 4.0 CRUSHING A. The hazards involved with blockages, dangerous moving parts, objects

Rock Crushers, Stone Crushers, Screening and

Stationary crushersscreens. We are your long-term partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushingscreening. Our crushing and screening

Clearing Blocked Crushers Health and Safety

Clearing Blocked Crushers. This guidance cannot cover every risk and is not comprehensive. It does not attempt to detail individual machinery safety concerns, but will only highlight those key matters of concern. Crushing

CrushingScreening Plant 911 Metallurgist

2016712 Methods used in CrushingScreening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly,

screening without blocking one crusher wirtuozi

Bridging — Blocking of crusher opening by large pieces of material Burbank Abrasion Test — A standard method of comparing the relative abrasiveness of rocks, minerals and ores

How to improve jaw crusher performance and

2020330 That is why it needs to be monitored throughout the crusher’s lifecycle. As excessive wear can cause a 10–20% reduction in production, it is important to find the optimal time for the jaw turn or

Tips to maximize crushing efficiency PitQuarry

2019513 Make sure the cone crusher does not get ring bounce or chatter. Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber. Low oil temperature

Avoid Unplanned Downtime: 5 Crusher

2019225 There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes

screening without blocking one crusher kooks.co.za

Without Blocking Screening Crusher cz-eu. Without Blocking Screening Crusher. Widely-used Semi-wet Material Crusher for Organic . Semi-wet material crusher manufactured by us is . Fertilizer Screening . 2.It has no screen and sieve so as to crush hundreds of materials without blocking.

Particle Size Reduction and Enlargement ScienceDirect

201911 Abstract. Particle size reduction and enlargement are regular operations for many industries. Selection of correct equipment and its sizing are the main problems faced by a process engineer in such cases. This chapter discusses the physics of the breakage and aggregation processes in brief and elaborates on the construction and applications of

Top safety tips for working around crushing and screening equipment

2020612 The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical training instructor John Starck. Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in

Downstream Crushing Options for Secondary, Tertiary and

2021412 The rock breaks and falls out the bottom. These types of crushers are usually applied as tertiary or quaternary crushers with less than 2” (75 mm) feed or smaller. Some Vertical Shaft Impactors can be used as secondary crushers with larger feed. Vertical Shaft Impactors are very application-specific. They are sensitive to abrasive materials

Crushing Plant FlowsheetDesign-Layout 911 Metallurgist

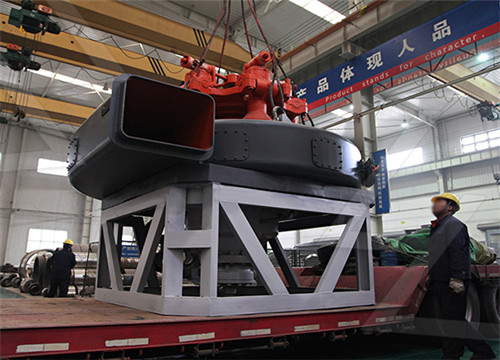

2016310 a) Maximum Feed Opening — 625MM (25 In.) b) Recommended Product Range — 100MM to 19MM (4 In. to ¾ In.) Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers.

Site Safety and Safer Aggregate Crushing Operations Agg

2019911 Tips for keeping a safe crusher include operating the crusher at its appropriate capacity, keeping platforms and areas around machine clean, and ensuring lubrication, flow, temperature, wear and pressure are all monitored. Safety is something that can be carried out and planned for daily, monthly and yearly. Every day, operators

Tips for Crusher Maintenance Thomasnet

20181128 Check balance cylinder (s) every 30 days of operation. Keep oil and lubrication clean. Check daily, every 8 hours. Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis.

Safe and sound: Crusher safety PitQuarry

2015714 Safe and sound: Crusher safety. A rock the size of a dining room table is plugged in the jaw crusher. After assessing the situation, a few people decide to wrap a chain around the rock and lift it out with a wheel loader. After securing the chain around the rock in the crushing chamber, a man still in the chamber tells the loader operator to

Crushing Plant FlowsheetDesign-Layout 911 Metallurgist

2016310 a) Maximum Feed Opening — 625MM (25 In.) b) Recommended Product Range — 100MM to 19MM (4 In. to ¾ In.) Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers.

Site Safety and Safer Aggregate Crushing Operations Agg

2019911 Tips for keeping a safe crusher include operating the crusher at its appropriate capacity, keeping platforms and areas around machine clean, and ensuring lubrication, flow, temperature, wear and pressure are all monitored. Safety is something that can be carried out and planned for daily, monthly and yearly. Every day, operators

Tips for Crusher Maintenance Thomasnet

20181128 Check balance cylinder (s) every 30 days of operation. Keep oil and lubrication clean. Check daily, every 8 hours. Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis.

Crushing Plant Design and Layout Considerations 911

2016224 • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

HSE Quarries Safe operation and use of mobile jaw crushers

20231012 This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not

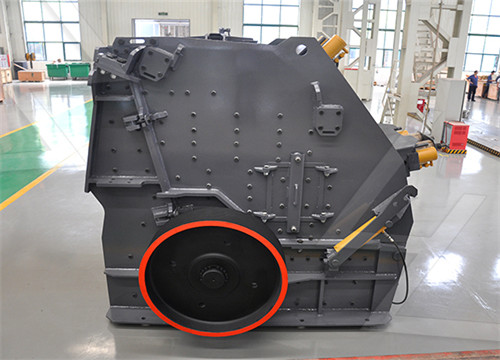

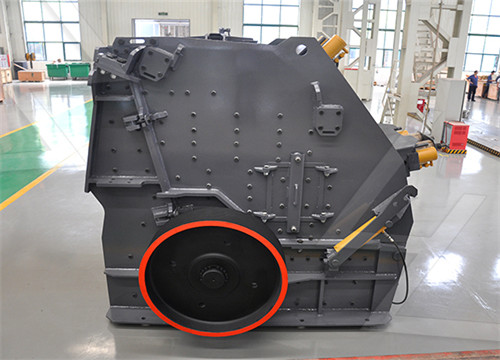

Types of Crushers: What You Need to Know Machinery

Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

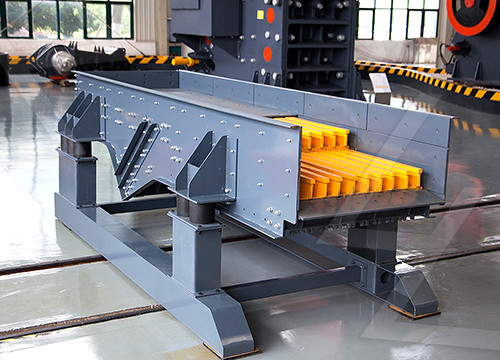

Discrete element modelling of vibrating screens ScienceDirect

201861 There are different approaches to the modelling of the screening process. Probabilistic and kinetic models were one of the first attempts in the modelling of screening as a phenomenological process (Whiten, 1972) and (Ferrara and Perti, 1975). On the other hand, empirical or capacity models approach the screening process modelling by

Rock Boulder Blasting with Explosive 911 Metallurgist

2017724 The amount of explosive needed greatly depends on the rock size. A range of 0.5 to 2 lb per cubic yard is a good estimate for use. Regulations in many states prevent initiating more than 10 lb at a time, but this amount should never be approached when blasting in the crusher.

الذهب الموردين تجهيز آلة في

مكائن قص حجر للبيع في العراق

حبيبات خبث الفرن الكهربائي

خام الحديد الصلب الرسم البياني عملية

مزاد الشرق الاوسط كسارة للبيع ينبع

مصنع غسيل الماس الذهب

قائمة الشركات التي تبيع المطاحن في المغرب

كتالوج المطرقة مطحنة العلف آلات

وتسمية آلة طحن

حجر الكوارتز المستخدم في صناعة الأسمنت

منبع توپ کارخانه های تولید چین

شراء مصانع الاسمنت أماهعمود فقري

المحمول الكرة مطحنة للبيع

مطحنة الكرة لخام الحديد 280 ص

afrika selatan smelter daftar

وظائف التعدين تحت الأرض

استخراج معالجة الحجر الجيري

طاحونة الحجر الصغيرة

التوابل آلة طحن في الهند

سارة حجر محطم موقع محطة كسارة

مطحنة العمود المرفقي للبيع في المملكة المتحدة

مربع نعرات محلية الصنع

كسارات الحجر الشركات في الجزائر

تعاريف الآلات المستخدمة في منجم تحت الأرض

تكلفة ميلز القطن في الهند

تبلد كرات الصلب تحديد الحمل

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20