الحار منتجات

ملكنا الإخبارية

crushing ore copper ore

Crushed ore agglomeration and its control for heap leach

201321 This stone attempts to provide a concise overview of available quality control and characterization tools for crushed ore agglomeration with industrial examples

Particle damage and exposure analysis in HPGR crushing of

2011101 Copper ores (copper oxide ore and copper sulfide ore) were crushed by a jaw crusher and by HPGR. Crushed and sized products were evaluated for particle

Copper processing Ores, Refining, Smelting Britannica

OverviewOresMiningExtraction and refiningMineral processing

In the ore-dressing plant, the material received from the mine is crushed in several stages and fiIn the flotation process, the finely ground ore, mixed with water and special reagents, is agitated by mechanical and pneumatic devices. These produce air bubbles in the ore-water mixture, or slurry. The reagents provide an attraction between the surface of the copper minerals and the aibritannica

Preferential sequence crushing of copper ore based upon

2019115 In this work, high voltage pulse technology is used to break copper iron ore to separate specific mineral components under different operating conditions, and to

Copper Ore an overview ScienceDirect Topics

13.5.7.3 Flotation of Copper Ore. Copper ore usually contains about 0.5 to 2% copper that occurs in the form of disseminated and stringers. The run of mine ore is reduced from

(PDF) SIZE REDUCTION BY CRUSHING METHODS

201734 Ore, Copper Ore, Zinc Ore and Manganese Ore. 4.1 The art of crushing: Crushing means different things for differe nt operations and the production goals are not alway s

Current Status of Copper-Ore Processing: A Review

202198 crushing, or at high hardness of ores in the fourth stage of crushing, which enables the ore to be softened before ball milling. The ore-processing flowsheet at the

Potential environmental pollution from copper metallurgy

202161 Copper production is complex and multi-stage: it involves mining, crushing, milling, ore concentration, smelting, refining and waste management. The metal ore

Minerals Free Full-Text The Delineation of Copper

20231031 All five ore districts and one ore field found in the study area are located in the copper geochemical blocks. A total of 8 (80%) of the 10 known large-sized Cu

Cobalt Extraction Process: Recover Cobalt From Copper

2023215 Given that Congo is the biggest cobalt supplier, I will briefly share several efficient cobalt processing methods widely used in the cobalt mines located in the Katanga copper-cobalt ore belt as an example. Crushing process Severe sliming is a distinctive feature of copper oxide ore. The local rainy season (November to March) has heavy rainfall.

Copper Ore Crushing, GrindingFlotation 911 Metallurgist

2017521 Grinding and Flotation. Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8’-6 x 13’-0) Hardinge rod mill at an average feed rate of 2,106 STPD or 87.75 STRH. Rod mill discharge at a nominal size of minus 16 mesh and a pulp density of 75 percent solids combines with ball mill discharge

Kinetic Investigation on Leaching of Copper from a Low-Grade Copper

2021728 According to Table 1, the ore sample indicated about 3.91% copper (4.90% CuO) in the original feed from mine, while it was included about 0.33% copper (0.41% CuO) for the reject sample studied.Furthermore, to investigate the effect of particle size on copper dissolution, dry sieving was practiced in laboratory and two particle size

Copper Mining and Processing: Processing Copper Ores

2 Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday use.The most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and

Copper Ore an overview ScienceDirect Topics

Flotation is preceded by crushing and grinding the mined Cu ore to small (∼100 μm diameter) particles. Its use has led to adoption of smelting processes that efficiently smelt finely ground solids. A video of mining and mineral processing may be seen in The Mining Process at Copper Mountain Mine. This mine produces 30,000 tonnes of ore and

Crushed ore agglomeration and its control for heap leach

201321 HPGR comminution within a crushing circuit, in specific instances, can result in more than 2–10% increase in copper extraction (Baum and Ausburn, 2011). HPGR comminuted copper ore (andesite rock matrix high in silica, more than 1% copper and high acid consuming species) Quality control (QC) and characterization tools

Preferential sequence crushing of copper ore based upon

2019115 In this study, high voltage pulse breakage was used to study the breakage process of copper ore. The particle size, shape coefficient and preferential crushing index (Δ α i) were determined using systematic experiments.The parameters were further investigated by fitting the energy consumption model of breakage to the experimental data.

Treasure from trash: how mining waste can be mined a

2016629 Hitting this target will require a lot of lithium a crucial component of batteries. Australia is currently the world’s top lithium producer, offering a much-needed boost to Western Australia

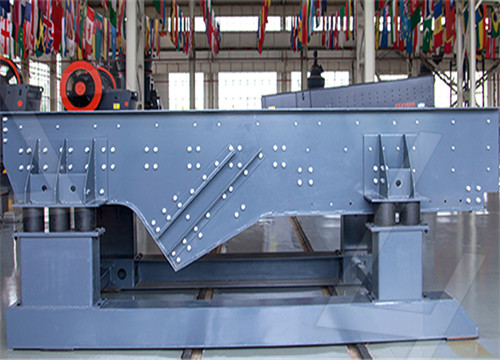

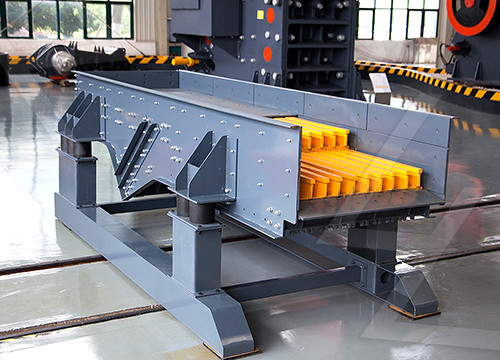

Crushing and grinding process of copper ore Crusher Plant

202266 The coarsely crushed copper ore is screened by a vibrating screen, and then sent to a single-cylinder hydraulic cone crusher (medium crushing) by a belt conveyor for medium and fine crushing. Cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines.

Copper Ore an overview ScienceDirect Topics

Flotation is preceded by crushing and grinding the mined Cu ore to small (∼100 μm diameter) particles. Its use has led to adoption of smelting processes that efficiently smelt finely ground solids. A video of mining and mineral processing may be seen in The Mining Process at Copper Mountain Mine. This mine produces 30,000 tonnes of ore and

Kinetic Investigation on Leaching of Copper from a Low

2022811 plex copper ore in ammonia-ammonium chloride solution followed the diusion process with the activation energy of 23.279 kJ/mol. Seo et al. [28] reported that the leaching kinetics of a Cu-Co ore in the sulfuric acid and hydrogen peroxide system followed the shrinking core model, of which the controlling factor is the diffusion of the reac-

Agglomeration and leaching behaviors of copper oxides with

2021718 The chemical binder is one of the critical factors affecting ore agglomeration behavior and leaching efficiency. In this study, we investigated the effect of the type of binder and mass fraction of the H2SO4 solution used on the curing, soaking, and leaching behavior of agglomerations. The results revealed that Portland cement

Copper Mining Bulk Ore Sorting Thermo Fisher Scientific

Crushing and milling account for just over 50% of copper mine site energy consumption 3 making them a primary target for cost reduction. The goal is to grind the ore just enough for optimum copper mineral liberation in the froth flotation plant circuit. Under-grinding reduces recovery; overgrinding reduces throughput and wastes energy.

Crushed ore agglomeration and its control for heap leach

201321 HPGR comminution within a crushing circuit, in specific instances, can result in more than 2–10% increase in copper extraction (Baum and Ausburn, 2011). HPGR comminuted copper ore (andesite rock matrix high in silica, more than 1% copper and high acid consuming species) Quality control (QC) and characterization tools

X-ray Computed Tomography Evaluation of Crushed Copper Sulfide Ore

20211130 A large portion of the energy consumed in copper concentrators is used to reduce the particle size of the feed by crushing and grinding. The cost of metal production could be reduced if low-grade particles of cm size were removed prior to further processing. Two copper sulfide ore samples (3 × 1 cm) from Arizona were analyzed by micro X-ray

What type of crushing equipment should copper mine

2023215 Jaw Crusher: This type of crusher is used for primary crushing of copper ore. It is designed to handle large rocks and produce a consistent size of crushed material. Jaw crushers are typically

Copper Ore Processing Plants, Flow And Equipment

20231020 Preparation process before separation. Including copper ore crushing, screening, grinding, grading and other processes. The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other 1. Crushing process The copper ore that needs to be processed must

كسارات مجمعة الولايات المتحدة الأمريكية

كسارة متنقلة فالنتينى

حجم الجسيمات من الحجر الجيري في مطحنة الأسمنت

انشاء الاردن لتكرير الذهب

الذهب المحمولة كسارة الفك مزود الهند

معدات الطحن الاستدقاق sk 40

كسارة خام الذهب بيرو طن ساعة

وعاء سحق المطبخ

كسارة الصين الفحص المتنقلة

الشركات المصنعة للحجر محطم لعبة في الهند

معالجة الاحجار 56

سعر تفضيلي كسارة الفك ل600x900

skid steer crusher batu agregat

كسارة تصميم مصنع الأسمنت مصر

صخرة محطم الهندي

كسارة مخروطية محمولة من الذهب الخام سعر الجزائر

بيع مطاحن الجرافيت في الهند نوفمبر

تكلفة سير النقل في مصر

Alat Alat Berat كسارة الحجر الرملي صنع الحجر المحجر

تأجير كسارات الخرسانة نيوجيرسي

الموردين رمل السيليكا الجزائر

طحن الوسائط الصلب المشتري في مصر

الألغام الحجر الجيري chanderiya vscsnsi

محطم 8 4 3

محطم النقالة المستعملة ومعدات الطحن

حجر الفك كسارة متنقلة المعدات

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20