الحار منتجات

ملكنا الإخبارية

2460 Circular Vibrating Screen Technical Parameters

Dynamic characteristics analysis of a circular vibrating

2023629 study takes the 2460 double-layer circular vibrating screen as the research object, applies Creo to build a three-dimensional model of the vibrating screen, and uses

Characteristics and efficiency of a new vibrating screen with

2013101 A mechanical model of the new motion was established and the characteristics of the new vibrating screen were analyzed to establish its equation of

Characteristics and efficiency of a new vibrating screen with

2013101 A mechanical model of the new motion was established and the characteristics of the new vibrating screen were analyzed to establish its equation of

Optimisation of a circularly vibrating screen based on DEM

201741 The vibration intensity of the screen is a key parameter affecting the screen performance which can be characterised by the vibration frequency f (cycles per

Present Situation and Development of Vibrating Screen

20211124 circular vibrating screen and linear vibrating screen. The circular vibrating screen is mainly used for preparation screening and final screening, and the linear

Journal of Physics: Conference Series PAPER OPEN

2022518 quality of the vibrating screen. Vibrating screen: the source of vibration is the centrifugal force generated by the rotation of a group of eccentric blocks, thus driving

Dynamics and screening characteristics of a vibrating screen

200971 Vibrating screens, such as linear vibrating screen, circular vibrating screen or elliptical vibrating screen, have a simple translational motion. The motion follows the

Stepwise shape optimization of the surface of a vibrating screen

2021101 Wide application of the discrete element method has sparked much research on the vibrating screen, which is a screening apparatus having a specific

(PDF) Optimal Design of Large Circular Vibrating

20141224 The analysis of the optimal vibrating screen presents that the mass of vibrating screen decreases by 3.5%, elastic deformation frequency which is close to the working frequency increases by...

(PDF) Screening Efficiency Analysis of Vibrosieves

201761 Factors that depend on the design of the equipment used belong to a second group, and includes the shape and size of the screen openings [5,8,11,12,20,26,27], type and material [5,8], screen...

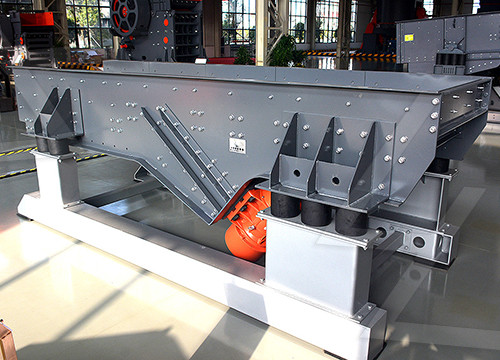

mpl Yk Series Circular Vibrating Screen

20231017 Circular Vibrating screen Introduction YK series vibrating screens are specifically designed for screening mineral stones at the working site. This series feature of various models,

Structural Analysis and Optimization Design of Linear Vibrating Screen

202035 3.2 Dynamic Analysis of Vibrating Screen. Since the vibrating screen is an inertial screen, during the vibration process, the force generated by the eccentric mass of the exciter is mainly driven; that is, the inertial force plays a leading role, and the spring restoring force and the damping force are negligible [].Therefore, in the dynamic analysis of the

YZS Series Circular Vibrating Screen Shanky Machinery

YK series circular vibrating screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device. Its vibrating track is a circle and moves on a circular motion. It is a multi-layer and high efficient vibrating screen. Motor drives the V-belt to make the eccentric block rotate in high speed, so that producing large

(PDF) Design and structure optimization of a reconfigurable vibrating

201669 By means of MATLAB optimization technology, the optimal mathematical model of linear vibrating screen is established.On the basis of the actual design parameters for the 27m2 linear vibrating

Variable elliptical vibrating screen: Particles kinematics and

2021111 The circular punching screen surface was used, with the mesh size of 6 mm and the opening rate of 45.09%. the vibrating screen was a typical low-frequency vibration equipment, and the kinetic energy and dissipation of the particle bed increase with the bed height Kinematics of a novel screen surface and parameter optimization for

Dynamics and screening characteristics of a vibrating screen

200971 Applying multi-degree-of-freedom vibration theory, characteristics of the vibrating screen was analyzed. Kinematics parameters of the vibrating screen which motion traces were linear, circular or elliptical were obtained. The stable solutions of the dynamic equations gave the motions of the vibrating screen by means of computer simulations.

Circular Vibrating Screens Mining Screens DOVE

1 DOVE Vibrating Screens are powered with advanced Circular Vibration technology, which results in longer material sieves drip line and higher efficiency in screening and particles segregation. DOVE supplies the largest range of Circular Vibrating Screens, in 54 standard models, with capacity range of (10 1300) Tons/ Hour, with widths from

Comparison of flip-flow screen and circular vibrating screen

202291 Unlike the traditional vibrating screens, the VFFS is a two-body vibration system, including two vibrating bodies, comprising the main screen frame and a floating screen frame. In this , a single-deck type of 0827 VFFS excited by an exciter was designed and produced, and a five-degree-of-freedom translational and rotational

Vibrating Screen Henan Deya Machinery Co., Ltd.

2015617 Circular Vibrating Screen Technical Parameters; Circular Vibrating Screen Introduction. Circular vibrating screens operate on an inclined surface. A deck moves in a circle. Circular Vibrating Screen Technical Parameters. Model Mesh Area(m 2) Mesh size(mm) Capacity(m 3 /h) Power(kw) Weight(KG) Overall size(mm) 2YK 1225: 6: 4-50: 8

Optimal Design of Large Circular Vibrating Screen Based

20221130 OPTIMAL PARAMETERS DETERMINATION OF CIRCULAR VIBRATING SCREEN Before the optimization of the vibrating screen side plate, the optimal parameters of the structure of side plate need to be determined. The structure of side plate with stiffeners, angle stiffeners, mounting hole of shaft and vibration exciter is very complex.

Analysis of the dynamic forces acting on a vibrating screen

202151 Vibrating screens are equipment used in various industries, such as mining, steel and . Although it is simple to install vibratory equipment on a support structure, it is necessary to consider the static and dynamic forces caused by vibration. The present work aims to perform a dynamic analysis of a vibrating screen and measure the dynamic

Sensors Free Full-Text Trajectory Control for Vibrating Screen

202261 The article presents a method of vibrating screen trajectory control based on MR (magnetorheological) dampers applied in a screen suspension. A mathematical description of the dynamic screen model was derived, and parameters of this model were estimated based on experimental data from a semi-industrial vibrating screen. The

Dynamics and screening characteristics of a vibrating screen

200971 2) A theoretical kinematic analysis of the vibrating screen was done to study how varying different parameters affects the motion of the screen. Kinematics parameters of the vibrating screen that motion traces are linear, circular or elliptical are obtained. 3) Motion traces of total vibrating screen were gained through computer simulations.

Dynamic Characteristics of a Vibrating Flip-Flow Screen and

2020520 Deep dry screening is the key unit in mineral processing. A vibrating flip-flow screen (VFFS) can provide effective solutions for screening fine-grained minerals, and it has been extensively used in many industrial fields. An accurate dynamic model of VFFS considering the influence of materials is significant for its dynamic analysis and screening

Modeling and Dynamic Simulation of a Multi-slope Vibrating Screen

2022122 A wide variety of vibrating screens are operated in the raw material processing and aggregate industries. Vibrating screen is a common equipment in mining machinery and equipment, its vibration is mainly generated by the exciter to achieve, and the use of the exciter working conditions are harsh, and with strong vibration impact

Simulation of particles motion on a double vibrating flip-flow screen

202351 The dimensions and technical parameters refer to Fig. 5, which reflects the actual structure of the double vibrating flip-flow screen. Download : Download high-res image (203KB) Download : Download full-size image; Fig. 16. Numerical simulation of particle trajectories of different-sized particles in double vibrating flip-flow screen.

Dynamic design theory and application of large vibrating screen

200991 The eighth vibration mode The relative optimal parameters of vibrating screen were compared and the results were presented in table 4. The results show that the first elastic deformation frequency is lowed by 14.17%, the second elastic deformation frequency is reduced by 12.29% and the total mass of vibrating screen decreased by

Crushing Equipment Double Deck Rotary/Circular Vibrating Screen

2023731 Crushing Equipment Double Deck Rotary/Circular Vibrating Screen Sieve 2yk2460, Find Details and Price about Vibrating Screen Separator from Crushing Equipment Double Deck Rotary/Circular Vibrating Screen Sieve 2yk2460 Shanghai Zhongrui Environmental Protection Equipment Co., Ltd.

القرص المطاحن العمودية

محجر سحق بير

معدات تعدين الذهب للبيع على نطاق صغير

كتابة اسمي في الرمال على الانترنت مجانا

تولید و توزیع سنگ irion در جهان

بيع كسارة الفولاذ المقاوم للصدأ

amazoncouk الثوم محطم المطبخ أمبير أمبير المنزل

كسارة فكية متنقلة من موردي الأرجنتين 10 Tph

كسارة للتأجير فيها

كسارات الصخور الآلية

الحوض الصغير كسارة الفحم

چین تولید کننده موج شکن مخروط

المسمار السلطة حسابات التصميم الصحافة

الفك محطم سعر لوحات في الهند

المطاحن الرطب طحن للبيع

يمكن الكهربائية محطم مبدأ العمل

ناقلات طحن فحم الكوك

أفضل مدرسة لآلات التعدين في البنك مع

كسارات مجمعة في جورجاون

سينا بارو كسارة بيتون مطرقة ديجوال

كسارة فكية مصنوعة من

منافذ الطحن العمودي

اسم pudhukottai كسارة

آلة إعادة تدوير الطوب

المحمول 30 نغمة حجر حجر حجر آلة محطم

سنگ شکن سنگ و قیمت های خود را

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20