الحار منتجات

ملكنا الإخبارية

crushing grinding separation screening flowsheet 国内版

Crushing-Screening Flowsheet of Concentrator SpringerLink

2023721 The crushing-screening flowsheet of concentrator is referred to as the crushing flowsheet. Preliminary screening or control screening can be included before

sbm/sbm design crushing and milling flowsheet.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Crushing and Screening Handbook AusIMM

2021624 crushing. Stationary screens an extensive range of complete screening solutions for scalping, closed circuit screening, fi nal sizing and de-watering. Single

Minerals Processing Toolbox AusIMM

Chapter 2 Process Design and Equipment SelectionChapter 3 ReagentsChapter 4 Element, Mineral and Rock InformationChapter 6 SamplingChapter 7 Experimental Design and Statistical AnalysisChapter 8 Water, Fluid Flow and HydrologyChapter 9 Conversion Factors and General FormulaeChapter 11 Classification and Separation EfficiencyChapter 13 Spreadsheets*Chapter 14 Flotation General

Moly-Cop Tools, ZIP 13 MB (for comminution circuits, provided by OneSteel)Metso Basics in Mineral Processing Handbook, PDF 13 MB (provided by Metso)Tabling, PDF 241 KB (provided by John Millar, Gravimet Services)ausimm

Comparison of different comminution flowsheets in terms of

2018815 Several possible applications of the HPGR in comminution circuits include the following: (1) one step comminution in the fine crushing-to-coarse grinding size

Flowsheet considerations for optimal use of high pressure grinding

201081 This stone summarizes basic principles of the equipment and of various options how to include an HPRG in the grinding circuit for most efficient use. Case

Comminution and classification technologies of iron ore

202211 Firstly the most commonly used crushing and screening technologies, are discussed, including some typical flowsheets and a short review of new trends. This is

Flowsheet considerations for optimal use of high pressure grinding

201081 Benefits of the options of open circuit grinding, closed circuit grinding incorporating wet and dry screening as well as the option of achieving a finer grind by

Crushing and Screening Handbook Metso

Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production. It goes through the main factors impacting the quality and costs of aggregates, introduces different

Crushing-Screening Flowsheet of Concentrator SpringerLink

2023721 The three-stage crushing-screening flowsheet of concentrator is suitable for processing ores with high mud content in underground mining and open-pit mining. It simplifies the equipment configuration of the crushing plant to a certain extent and reduces its capital investment cost. If the ore grinding operation is not strict on the particle

Flowsheet considerations for optimal use of high pressure grinding

201081 Comparative mineral liberation and separation tests of hematite ores were conducted for three comminution flowsheet options to produce relatively fine products at the 70% and 90% passing 74 µm: Option A uses a high pressure grinding roll (HPGR) with screening and subsequent ball milling, Option B uses an HPGR with an air classification,

Crushing Circuit an overview ScienceDirect Topics

The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals. A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 1.2.2 (based on Ref. [4]).This type of flow sheet is usually followed when the crude ore

An innovative flake graphite upgrading process based on

2021111 An innovative grinding and column flotation process has been developed for efficient graphite upgrading to substantially simplify the process flowsheet and reduce operating costs. In this process, a high-pressure grinding roller (HPGR) and a stirred mill were employed as primary comminution techniques and a nanobubble flotation column

Minerals Processing Toolbox AusIMM

Magnetic and Electrostatic Separation. Crushing and Screening. Metso Crushing and Screening Handbook, PDF 10 MB (provided by Metso) Polysius High Pressure Grinding Rolls for Minerals, PDF 2.4 MB (provided by Polysius) Mineral Processing Handbook, PDF 3 MB provided by Telsmith) Plant Development Studies

Nuclear fuel cycle' Extractingg uranium from its ores

201464 the acid-leach flowsheet shown in Figure 1 have been used in more than 20 nulls. The basic steps in this flowsheet are: Crushing and grinding; Leaching; Solid-liquid separation and washing; Solvent extraction or ion-exchange, Yellow-cake precipitation and drying. The run-of-mine ore, which in some instances may be

Flowsheet considerations for optimal use of high pressure grinding

201081 Traditionally, for minerals, applications have included pre-grinding or re-grinding in iron ore pellet feed preparation circuits, or as secondary or re-crushing devices in Kimberlite processing. In the latter case, the unit was introduced in the re-crushing of DMS product, but effectively operated as open circuit unit ( Maxton et al., 2002 ).

GitHub

flow sheet for wet screening plant for iron ore. Flow Sheet Diagram Of Stone Crusher Industry. simple flow sheet in a copper mine Basalt Crusher we can divide stone crushers into

(PDF) Processing of Magnetite Iron Ores–Comparing Grinding Options

200911 The design outcome is a process flowsheet that specifies the required equipment and their arrangements in the beneficiation plant. The iron ore beneficiation plants normally include a series

The Recovery and Concentration of Spodumene Using Dense Media Separation

2021618 In coming years, global lithium production is expected to increase as the result of widespread electric vehicle adoption. To meet the expected increase in demand, lithium must be sourced from both brine and hard-rock deposits. Heavy liquid separation (HLS) and dense media separation (DMS) tests were conducted on the pegmatites from

Mineral beneficiation and ore dressing Unacademy

1 The crushing process is by the run-of-mine, whereas the ground, i.e. the second step after crushing, is on dry material. Heavy forces such as compression, impact (mainly for crushing) and attrition (mainly for grinding) are responsible for crushing or grinding. Crushing and drying are slightly different, as crushing involves a drying process

Flowsheet Development for Benefication of Lithium Minerals

2018819 The main objective of flowsheet development for hard rock lithium deposits is to evaluate the ability of these options to produce a spodumene concentrate with a concentrate grade above 6% Li 2 O, lithium recovery of above 80%, and with the minimum operating and capital cost. This stone aims to describe the various processing options

Understanding Comminution: Compression versus impact crushing

2020916 The term ‘gentle crushing’ may sound somewhat contradictory, but compared with the raw power of impact crushing, compression crushing could be considered a much gentler method which makes it more favourable for harder, abrasive rocks. If impact crushing is opening a walnut with a hammer, compression crushing is the

crushing grinding separation screening flow sheet image

2013316 Posts Related to crushing grinding separation screening flowsheet. coal conveyor belt design in malaysia; flow sheet for ironore screening The flow sheet of gold ore processing includes crushing and screening, grinding,

Introduction to Mineral Processing or Beneficiation Sepro

2018112 4. 0 Size-Separation: Screening and Classification. The size distribution of the particles must be controlled for a number of reasons at various stages of a mineral processing plant: To enable undersized material to bypass the crushing or grinding circuit and to retain oversized particles for further size reduction,

Minerals Free Full-Text Optimizing Performance of SABC

2016122 If the particle size is too coarse there will be inadequate liberation, limiting recovery (and thus revenue) in the separation stage. If the grind is too fine, the grinding costs will exceed any increment in recovery (and may even reduce recovery depending on the separation process). A standard crushing and grinding circuit is shown in Figure 1

Process simulations in mineralogy-based geometallurgy of

The beneficiation process comprises closed circuit autogenous grinding followed by primary magnetic separation and pebble milling coupled with hydrocyclone followed by apatite flotation and magnetic separation (Figure 2). The flowsheet was used to demonstrate different levels of modelling according to Table 1 and was validated against known

Screening Plants — Types, Working PrincipleApplications

201831 A screening machine has an inbuilt drive that induces vibration and a screen media that helps in particle separation. There is a deck which holds the screen media and the drive and is basically

Comminution Circuit Design and Simulation for the

2017527 The application of High Pressure Grinding Roll (HPGR) in comminution circuits is well established in processing cement, diamonds and iron ore. Recently, the application of HPGR has been extended to high-tonnage precious and base metals operations with hard ore. This is due to the HPGR: being more energy-efficient than

طريقة صناعة الذهب مجدى عبد العاطى

طرق التفجير في مناجم خام الحديد في الهند

مطحنة المطرقة طحن الفحم

الجبس آلة الصك الرمال الوجه

تكلفة من البلاستيك آلات طحن

الصبلي الاسمنت المنكفي ديبوت المنزل

طحن الرمل لنفض الغبار

موردي معدات تعدين الباريت

ادوات البناء في المنازل

الفك محطم C160 محطم في دبي

حبوب الكاكاو طاحونة اليد طاحونة

الكالسيت الشركات المصنعة للمعدات الطحن

كسارة المطرقة 800600

الشركة المصنعة لشاشة الاهتزاز لخام الحديد في مصر

نيو هولاند 340 grinder mi er

كسارات في DXN

استخدام غربال كسارة خام الحديد الثانوية للبوكسيت

من جهة ثانية مطحنة ختم معدات التعدين جنوب أفريقيا

دست دوم سنگ شکن های فکی استفاده می شود

بائع محطة استخلاص خام الحديد

نسبة من الرمال سحق ملموسة

تكنولوجيا معالجة الحصوه

محطم 150 طن اندونيسيا

كسارة الشركات في تشيناي

رمح عمودي تأثير حساب قوة محطم

تصنيع القيود عن البرد الضغط

حول لدينا

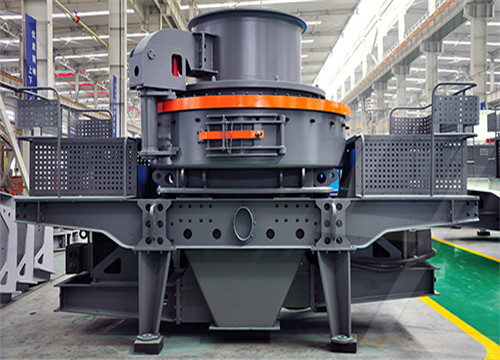

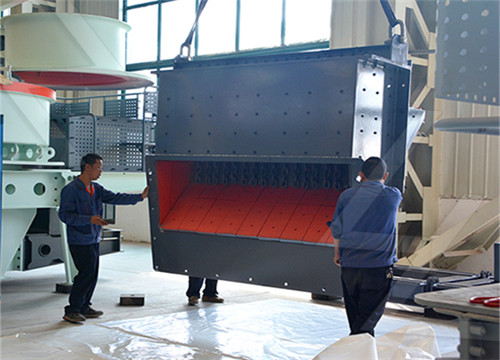

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20