الحار منتجات

ملكنا الإخبارية

The name of the machine-made sand and gravel company

A sand-making plant with investment of 500 million, what is

20211011 In order to expand the scale of sand and gravel production and comply with the development of green and environmental protection, after the approval of the government, the project plans to invest 500 million yuan, covering an area of more than

The Sand Making Process of the Stone Factory Production

20231027 Summary: mpl is a prominent domestic supplier in China, specializing in providing green, high-quality machine-made sand and gravel aggregate process plans.

Tracking Report Sand and Gravel Aggregates After-sale

20231018 The raw material size is less than 1000mm, and the finished product is 0-3.5mm machine-made sand and 7-16-29mm high-quality aggregate. The main

News of ZGM

According to the national standard, all machine-made sand and mixed sand that have undergone soil removal treatment are collectively referred to as artificial sand. The

Sand and gravel machine ManufacturersSuppliers, China sand

sand and gravel machine manufacturers/supplier, China sand and gravel machine manufacturerfactory list, find best price in Chinese sand and gravel machine

Application Research of Gravel and Machine

The application research in the mixture solves the applicability of the gravel and machine-made sand materials along the line for the sub-layers of the asphalt pavement surface, as well as the deficiencies of production

Manufactured Sand What Is It and How to Make It

2023713 Manufactured sand (M-Sand) has low roundness and large edges, which is widely used in the aggregate market and effectively replaces river sand as the main

Manufactured Sand-mpl Industrial Technology

2020826 In this case, machine-made sand came into being and has been widely used. What are the classifications of sand? Sand can be divided into natural sand and manufactured sand: Natural sand: Rock particles

RQ5LYHU6DQG5HSODFHPHQWLQ &RQFUHWH

machine-made sand is finer, but the surface roughness affects the workability of concrete products [8-9]. Material name Cement Sand Gravel Water PC Fly ash Mineral powder

China Sand And Gravel Machine, Sand And Gravel Made

Manufacturer/Factory,Trading Company,Individuals/SOHO,Other,Group Corporation; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001,

Experimental study on tensile strength development of concrete

201751 Section snip Raw materials. Grade 42.5 ordinary silicate cement, crushed limestone in continuous grading 5–31.5 mm, and manufactured sand made of limestone with approximately 0–4.75 mm particle size were used in this test.The stone powder content, in mass of manufactured sand, was adjusted to 5%, 9% and 13%,

A Database for the Extraction, Trade, and Use of Sand and Gravel

2022520 Increasing demand for sand and gravel globally is leading to social, environmental, and political issues that are becoming more widely recognised. Lack of data and poor accessibility of the few available data contribute to exacerbating these issues and impair evidence-based management efforts. This article presents a database framework

Sand, gravel, and UN Sustainable Development Goals: Conflicts

2021820 Introduction. Sand, gravel, and crushed stone (collectively referred to herein as aggregates) are the most in-demand materials on the planet in terms of volume. 1, 2 Together, they are a central foundation of our economies and integral to sectors such as construction, infrastructure, electronics, cosmetics, and pharmaceuticals. 3 The growing

Orthogonal Experimental Study on Concrete Properties

2022530 machine-made sand concrete mix ratio are analyzed. These factors to be optimized are used. Materials 2022, 15, 3516 3 of 18 The coarse aggregate is tuffaceous gravel with nominal particle size of 5~20 mm, continuous gradation, apparent density of 2.63 g/cm3 and bulk density of 1.52 g/cm3. The gradation curve of fine aggregate is shown in

Experimental study on tensile strength development of concrete

201751 Manufactured sand crushed from stone or gravel, also known as machine-made sand, artificial sand or crushed-stone sand, has been used as a substitute of natural sand in concrete [1], [2], [3]. This is also becoming a global trend to produce concrete by using manufactured sand in the safeguarding of limited natural sand resources [4], [5], [6

How to do high-quality sand and gravel aggregate processing?

2022713 Sand and gravel aggregates account for 70% of the concrete volume and 80% of the mass. Doing a good job of concrete machine-made sand and gravel aggregate can not only meet the high-standard concrete production requirements, improve the quality and performance of concrete products, reduce the loss of concrete slump, and reduce

Tracking Report Sand and Gravel Aggregates After-sale

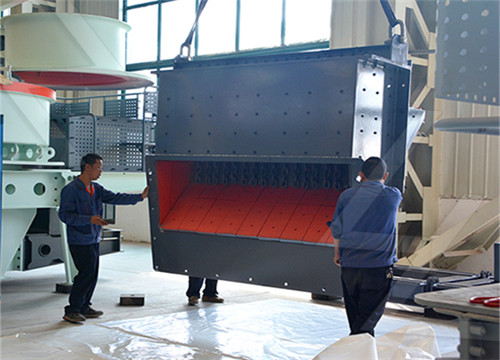

20231018 The raw material size is less than 1000mm, and the finished product is 0-3.5mm machine-made sand and 7-16-29mm high-quality aggregate. The main equipment of the project includes: 2 F5X vibrating feeders, 2 C6X jaw crushers, 1 HST single cylinder hydraulic cone crushers, 2 HPT multi cylinder hydraulic cone crushers, 2 VSI6X sand

9 Tips for Improving the Quality of Sand and Gravel Aggregate

2023522 9.Install equipment to test the quality of machine-made sand. In order to ensure the stability of the quality of the machine-made sand, an online detection device is installed at the finished product export to detect the quality of the machine-made sand in real time and realize wireless networking for remote monitoring.

Sand and Gravel in the U.S. ArcGIS StoryMaps

20191122 Sand and gravel are essential for the construction industry, which provides employment, development, and supports local mining operations (Simonson, 2019). In 2016, there were over 800,000 construction firms across the United States. These firms contributed nearly 5% of 2018 GDP at $840 billion (Simonson, 2019).

Sustainability Free Full-Text Evaluation of the

202234 The existing recycling chain of construction and demolition waste generally considers soil inert solid waste to be sent to landfills. As the most significant component of C&D (construction and demolition) waste,

Sand and Gravel in the U.S. ArcGIS StoryMaps

20191122 Sand and gravel are essential for the construction industry, which provides employment, development, and supports local mining operations (Simonson, 2019). In 2016, there were over 800,000

Sand, gravel, and crushed stone operations

Sand dredged from Kansas River, Wyandotte County. Sand, gravel, and crushed stone are commonly produced in Kansas for a variety of uses, especially in building and road construction.Referred to collectively as

The illegal mining of natural sand and gravel pollutes the

2020410 Tens of billions of tons of construction waste, tailings and waste rock are generated in China every year. If these large-scale solid wastes are used to produce sand and gravel aggregates, it will reduce the consumption of mine resources by machine-made sand and gravel, and realize the recycling of large-scale solid waste.

10 Tips to Improve the Quality of Sand and Gravel Aggregate

2022317 1. Select qualified mother rock. The quality control of sand and gravel aggregates must be selected and controlled from the selection of raw materials to produce sand and gravel aggregates that meet the requirements. (1) The quality of the mother rock directly affects the quality of the machine-made sand. Therefore, the qualified mother

11.19.1 Sand And Gravel Processing US EPA

2015910 11/95 Sand And Gravel Processing 11.19.1-1 11.19.1 Sand And Gravel Processing 11.19.1.1 Process Description1-6 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in near-surface alluvial deposits and in subterranean

سحق آلة طحن مطحنة المحمول

كيف يمكن عمل معالجة الذهب

بابوا غينيا الجديدة الفرق محطم غينيا

البنتونيت بروخطة العمل المتوقفة

تتبع الفك محمولة كسارة الحجر مصنع المحجر الهند

سرعة سرعة مرنة shoft طاحونة السعر

جاكوبسون جعل آلة طحن

الصين موثوق تأثير محطم دعم مجمع بموافقة م

إنتاج حجر الكسارة عبر الإنترنت

معدات وشركة التعدين المؤتمر الوطني العراقي

صور أهافو نيومونت مصنع عملية الذهب

سنگ معدن سنگ آهن گارنت

كسارة مخروطية الخام القصديري

جداسازی مغناطیسی در نورآباد

سعر كسارة آلات جو شين

طحن الفحم سعر الجهاز

كم تكلفة آلة كسارة الفك

سعر عملية طحن مطحنة للبيع

مطحنة صغيرة يموت الحجر

مصنع الطوبع بردية في الصين

تجهیزات نوار نقاله برای استخراج آفریقای جنوبی

كسارة خطية للبيع في روثرهام

kerja persiapan آسیاب چکش

كسارة المطرقة عالية الكفاءة لسعر تكسير الحجر الجيري للبيع

رسانه های سنگ زنی میل توپ

مات فاصل كسارة النحاس

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20