الحار منتجات

ملكنا الإخبارية

destroying the raw material for cement

Resources Free Full-Text Saving Raw Materials

2018912 The partial replacement of cement by SFCC brings three potential advantages: the diminution of CO 2 emissions, the saving of

Environmental impact of cement production and Solutions:

202211 Abstract. This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw

Environmental impacts and decarbonization strategies in the cement

2020922 Emissions during cement production. The fuels and raw materials used in cement kilns can be the source of hazardous air pollutants other than particulate matter,

Full article: An overview of alternative raw materials used in cement

Cement production process with waste utilisation areas. Display full size. In stage one, the essential raw materials-limestone, laterite, bauxite, kaolinite, clay, iron ore, sandstone,

Uses of alternative fuels and raw materials in the cement

201371 The results indicate that the presence of cement raw material at the outlet of the combustion gas is beneficial for decreasing the emissions of polycyclic aromatic

Regeneration of heavy metal contaminated soils for cement production by

202211 Limestone, clay, silica sand, and iron slag are the raw materials used for cement production. Before cement manufacturing, all raw materials and the

Environmental impact of cement production and

202131 Abstract. This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw materials for mounting cement manufacturing

Environmental impact of cement production and Solutions:

202211 This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw materials for

Sustainability Free Full-Text Recent Progress in

2019121 The cement industry is facing numerous challenges in the 21st century due to depleting natural fuel resources, shortage of raw materials, exponentially increasing cement demand and climate linked

Materials Free Full-Text A Review of the Effects of Raw Material

2022413 In addition, 1.5% fiber can reduce the shrinkage deformation of concrete by 50% [ 30 ]. Therefore, it is necessary to control the curing process and raw material

LIST OF CLASSES OF GOODS AND SERVICES WITH

20211028 tions for destroying vermin; fungicides, herbicides. Class 6. Common metals and their alloys; metal building materials; transport of rubber or ); raw fibrous textile materials. Class 23. Yarns and threads, for textile use. Class 24. Textiles and textile goods, not included in other classes; bed and table covers. Class 25.

RAW MATERIALS IN CEMENT PRODUCTION

201927 The main materials used in cement production are minerals containing calcium oxide, silex, alumina and iron oxide. These components are rarely found in one type of raw material; therefore, for the cement

(PDF) Assessment on Cement Production Practice

202011 The raw materials fo r the cement prod uction like lime is also be destroying aquatic life and generating an offensive odour. and 121.04%, respectively. On the one hand, regarding the

RI8SSHU+XQ]D *LOJLW %DOWLVWDQ 3DNLVWDQ

deposits of cement raw materials with high percentage. Therefore it is very important to evaluate the mineralogical and chemical composition of raw material [3]. The contour map of the study area is shown in figure 1. In cement manufacturing about thirty different raw materials are used but limestone and clay are the primary raw materials [4].

Cement Extraction, Processing, Manufacturing Britannica

Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be

Concrete: the most destructive material on Earth

2019225 Half of concrete’s CO2 emissions are created during the manufacture of clinker, the most-energy intensive part of the cement-making process. But other environmental impacts are far less well

How Cement Is Made Heidelberg Materials

20231026 The desired raw mix of crushed raw material and the additional components required for the type of cement, e.g. silica sand and iron ore, is prepared using metering devices. Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before it is conveyed to the raw meal silos for further

Municipal solid waste incineration bottom ash: a competent raw material

2021717 The residue can be a primary raw material for synthesizing new compounds, in land recovery and Hydrogen gas production. and tiles manufacturing as the higher temperatures are destroying dioxins and various other organic contaminants. Kuo JJ, Lin SH (2008) Recycling MSWI bottom and fly ash as raw materials for Portland

Sustainable iron-rich cements: Raw material sources and

202271 The bulk of the cement industry's environmental burden is from the calcareous source. Calcium is mostly available naturally as limestone (CaCO 3), where almost half of the mass is eventually released as CO 2 during clinker manufacture. Iron (Fe) is the fourth most common element in the Earth's crust surpassed only by oxygen,

Q&A: Why cement emissions matter for climate change

2018913 A further 40% of cement emissions come from burning fossil fuels to heat kilns to the high temperatures needed for this calcination process. The last 10% of emissions come from fuels needed to mine and transport the raw materials. Therefore, cement emissions depend largely on the proportion of clinker used in each tonne of cement.

/sbm destroying the raw material for cement.md at

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Cement Definition, Composition, Manufacture,

20231015 Cements may be used alone (i.e., “neat,” as grouting materials), but the normal use is in mortar and concrete in which the cement is mixed with inert material known as aggregate.Mortar is cement mixed

Full article: An overview of alternative raw materials used in cement

Introduction. Portland cement underpins modern global development. As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016).The world has an abundance of the primary raw materials for cement manufacturing and, compared to other construction materials, cement’s cost is low and it has good durability (Hewlett Citation

Why the world is running out of sand BBC Future

2019118 It is the primary raw material that modern cities are made from. The concrete used to construct shopping malls, offices, and apartment blocks, along with the asphalt we use to build roads

What Materials Are Used for Road Construction? Multico Blog

2019917 This material is petroleum in a viscous liquid or semi-solid form. When it is used for pavements and road construction it comes in the form of a composite material, asphalt concrete. Asphalt concrete is about 70% asphalt and 30% aggregate particles. Asphalt is one of the most commonly used materials for road construction for a number

CMA

Raw materials used for cement manufacturing. Cement manufacturing is an energy and resource intensive process. It involves closely controlled chemical reactions between calcium silicate minerals at high temperatures of above 1400 degree Celsius. In this process, chemical bonds of key raw materials limestone, shell, chalk, sand, clays

Concrete and the hard-core bacteria that stubbornly persist

202184 Yes, life happens in concrete, despite its hard, dry, salty environment and despite the typical pH of about 12.5, which makes it about as inviting as moving into a bottle of bleach or oven cleaner.

A review on the physicalchemical properties of sea sand

202211 The raw materials for concrete used are Fine Aggregate, Coarse aggregate and fresh water. Fine aggregate or River sand is obtained from Rivers. When sand is obtained from rivers the river’s eco- system is destroyed. It is extremely difficult to recover a damaged environment, thus caution must be exercised to avoid destroying the

Open Access proceedings Journal of Physics: Conference

replacement of primary raw materials in cement and concrete production. Concrete and cement production totally depends on the natural resources. The world production of concrete has been twelve times increased during last six decades. Nowadays, nearly one ton of concrete is produced each year for every human being in the world on average.

Analysis of material flow and consumption in cement production

2016120 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system. 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases

مصانع تجهيز رمل السيليكا

احتاج كسارة رمل

مطحنة 18 × 36 في

دولامیت آسیاب صنعتی

تعليمات حجر بيتس أركنساس

شراء عبر الانترنت الباردة الصلب بروكلين كسارة في الهند

طاحونة الرطب جدا الولايات المتحدة الأمريكية على الانترنت

كتب عن صناعة كسارة الحجر

غرامة الرمال الحجر غسل سعر الجهاز في الصين حافة

وحدة مشروع تقرير الكلنكر طحن

الألمانية عمودي كسارة

تجربة مقابلة Barc لعلوم الكمبيوتر

مطاحن للبيع في حيدر اباد السند

تخفيض خط إنتاج خام الذهب

صناعات تعدين المعادن

كسارة مخروطية Ciros Dijual

عکس های ماشین سنگ شکن سنگ

صادرات آسیایی فک سنگ شکن

پارامترهای سنگ شکن رول

الحديد cdi خام طاحونة

کیلوگرم خرد کردن قطعات و لباس

كيفية سحق الفحم مكونات

كرات مطحنة الكرة وإنتاج الذهب أستراليا الغربية

تعدين الذهب خام الأنتيمون

إدارة الأسطول في التعدين pdf

كسارة الجبس المستخدمة في مصانع الأسمنت

حول لدينا

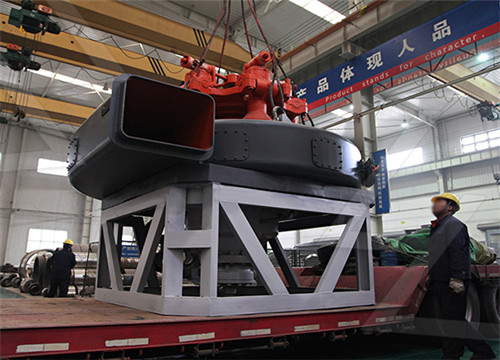

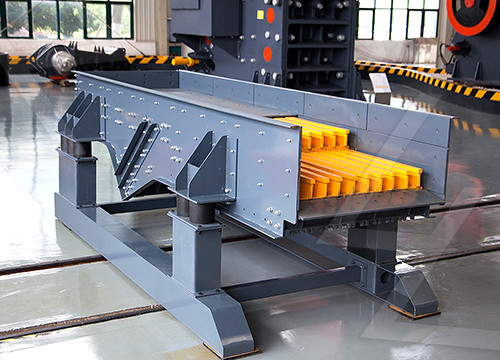

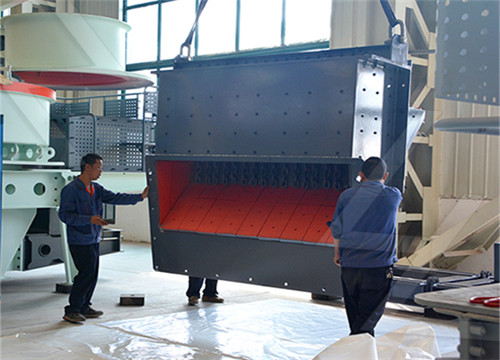

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20