الحار منتجات

ملكنا الإخبارية

cost of processing mill for red gram

Red gram milling unit as a rural entrepreneurship in tribal

2019429 The commercial dhal mill operators and dhal milling units run by farmer's producer's organisations are participating in the open tender system and sourcing the raw red gram at 42-45% lesser...

Red gram milling unit as a rural entrepreneurship in tribal

The commercial dhal mill operators and dhal milling units run by farmer’s producer’s organisations are participating in the open tender system and sourcing the raw red gram

Red gram milling unit as a rural entrepreneurship in

the open tender system and sourcing the raw red gram at 42-45% lesser price ranging from Rs. 3000 to 3500 when compared to minimum support price of raw red gram. Then the

sbm cost of processing mill for red gram.md main GitLab

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

An economic analysis of production and marketing of

CostA1, CostA2, Cost B1, Cost B2, CostC1, CostC2 and CostC3 of red gram were Rs 12858.77, Rs12858.77, Rs15858.77, Rs 16176.00, Rs 18508.23, Rs18825.46, Rs

Economic analysis of redgram production and marketing

The average production cost per quintal of Red gram was calculated to be Rs. 1800.35 respectively. The net income from Red gram and were calculated to be Rs.58360.78 per

ECONOMICS OF PROCESSING OF REDGRAM (CAJANUS

2021718 Redgram processing units had processed 31,636 quintals of redgram annually and total capacity utilization was 55.62 per cent. The total cost of processing of

(PDF) RED GRAM PROCESSING REPORT Sharad Pant

RED GRAM PROCESSING REPORT is the report prepared on the basis of practical experience of Red Gram processing. Before going for Red Gram Processing, If someone

(PDF) RESOURCE USE EFFICIENCY AND MARKETING OF REDGRAM

201846 Marketing costs born by producer, trader, processor, wholesaler and retailer were 149.28, 88.95, 134.10, 69.77 and 62.97 in channel I. Marketing costs born by

(PDF) Economic efficiency of improved red gram

201611 The results showed that the net return (with red gram as pure crop) was the higher ( 5, 629 per acre) for BRG2 red gram farms than ( 3, 936 per acre) for check variety farms, with a difference of

Agriculture Marketing AGMARKNET

AGMARKNET 28 Oct 2023: Wheat: 147 Average Max Price: 3000 Min Price: 2210 : Wheat: Bansi Max Price: 3060 Min Price: 2350 : Wheat: Dara Max Price: 2630 Min Price

Impact of Green Synthesized Metal Oxide Nanoparticles on

2020424 Abstract The present study emphasis on the synthesis of zinc oxide (ZnO) and magnesium oxide (MgO) nanoparticles (NPs) via a simple, eco-friendly and low-cost approach. The Aloe barbadensis Mill (Aloe-Vera) leaf extract was employed as a source of capping and reducing agents for the synthesis of ZnO and MgO NPs. The synthesized

(PDF) RED GRAM PROCESSING REPORT Sharad Pant

RED GRAM PROCESSING REPORT is the report prepared on the basis of practical experience of Red Gram processing. Before going for Red Gram Processing, If someone will refer this it will be very useful for the person to get the complete idea of the In the study area, farmer, Faria, 1 wholesaler, Aratdar 2 and feed mill were the market

Tandur Red Gram gets GI tag- The New Indian Express

20221215 HYDERABAD: The famous Tandur Red Gram is now a registered GI of Telangana. The GI Application No. 706 was filed on September 24, 2020 by the Yalal Farmers Producers Company Limited, an FPO.

GRAIN DEHUSKING MACHINES- A REVIEW IRJET

2020328 The literature survey call for developing a low cost and efficient grain processing machine for household with quality for sustainable agricultural production using human energy. Keywords: Threshing, Multistage Rice Mill (B) Wheat Dehusking Process The operation of detaching the grains from the ear head, cob or pod is named as

Mini Dal Mill Project Report, Business Plan Idea2MakeMoney

2021521 BEP% = Fixed Cost x 100/Fixed Cost + Profit = 14,01,320 x 100/14,01,320 + 33,55,400 = 29.4%. Assumptions in Mini Dal Mill Project. The production Capacity of Gram Chana Dal is around Rs. 400 kg per day. In the first year, Capacity; has been taken @ 60%. Working duration of 8 hours daily has been considered.

Global production, processing and utilization of lentil: A review

2017121 Introduction Lentil (Lens culinaris) is an edible pulse. It is also known as red dhal, masur or split peas and is considered an important source of dietary protein in the developing countries. It is an excellent source of complex carbohydrates and dietary fibres, vitamins and minerals (Adsule et al. 1989).

sbm cost of processing mill for red gram.md main GitLab

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

Pigeon pea — Vikaspedia

Pigeon pea. Pigeonpea ( Cajanus cajan (L.) Millsp.), commonly known as red gram or tur or Arhar, is a very old crop of this country. After gram, arhar is the second most important pulse crop in the country. It is mainly eaten in the form of split pulse as ‘dal’. Seeds of arhar are also rich in iron, iodine, essential amino acids like lycine

Economic analysis of redgram production and marketing

The average production cost per quintal of Red gram was calculated to be Rs. 1800.35 respectively. The net income from Red gram and were calculated to be Rs.58360.78 per hectare, respectively. There were three marketing channels was prevailing in the study area, i.e. marketing channel I- produced for consumer, channel II- produced village

Mini Dal Mill Project Report, Business Plan

2021521 BEP% = Fixed Cost x 100/Fixed Cost + Profit = 14,01,320 x 100/14,01,320 + 33,55,400 = 29.4%. Assumptions in Mini Dal Mill Project. The production Capacity of Gram Chana Dal is around Rs. 400 kg per

Global production, processing and utilization of lentil: A review

2017121 Introduction Lentil (Lens culinaris) is an edible pulse. It is also known as red dhal, masur or split peas and is considered an important source of dietary protein in the developing countries. It is an excellent source of complex carbohydrates and dietary fibres, vitamins and minerals (Adsule et al. 1989).

red gram mini dal mill project MC World

2021-12-04T23:12:26+00:00 red gram mini dal mill project bernavillebernch. A low cost source of high quality chana dal is Bob's Red Mill capital invt of besan mill in bengal project dal and besan mill plant bratsnewjersey the dal mill project was initiated by seva mandir, udaipur with the help of the since tur is a cash crop and theFeb 19, 2013 red gram mini

(PDF) Green gram production technology: An economic analysis

201943 The result showed that the recommended land use was adopted by green gram growers to the extent 95.83 per cent. sowing distance contributed 99.31 per cent at the highest level followed by sowing

(PDF) RESOURCE USE EFFICIENCY AND MARKETING OF REDGRAM

201846 Processing costs 270.35 397.41 290.42 426.91. The study was conducted in Gulbarga district of Karnataka as it contributed 60.92 per cent share in total production of red gram at state level

sbm cost of processing mill for red gram.md main GitLab

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

Pigeon pea — Vikaspedia

Pigeon pea. Pigeonpea ( Cajanus cajan (L.) Millsp.), commonly known as red gram or tur or Arhar, is a very old crop of this country. After gram, arhar is the second most important pulse crop in the country. It is mainly eaten in the form of split pulse as ‘dal’. Seeds of arhar are also rich in iron, iodine, essential amino acids like lycine

Model Detailed Project Report MP AGRO

2021114 Transportation Cost. 4.3 Power Requirement The borrower shall require power load of 6 KW which shall be applied with Power Corporation. However, for standby power arrangement the borrower shall purchase DG Set. 4.4 Manpower Requirement 8 Manpower are required for the Gram Based Dal Mill Includes: 1 Plant Operator 2 Skilled

500 طن لكل ساعة por لو تأثير كسارة تاجر

kilang bijih di uk

كسارة الأنقاض المتنقلة

طحن التوابل آلة

بناء الصور مصنع معالجة الغاز الطبيعي باكستان

معدات التعدين الصخور لفة كسارة

نوع رأس السلطة كسارة الحجر

آلة صنع مسحوق الحجر الأملس المورد

خام الجرافيت مينييرال

مخروط محطم المحمول في جنوب أفريقيا

آلة تكسير و طحن خام الحديد

كيف يتم استخراج الحجر الجيري التعدين 0

عايزة ماكينة انتاج اطباق الفوم

كسارات الصخور للبيع في سري لانكا اندونيسيا كسارة

cealy معالجة أمبير الألغام 3Bampamp الحجر الجيري ميامي

المملكة العربية السعودية تستخدم كسارة تصادمية محمولة

فواتير آلات زجاج محطم

تستخدم المجرة الكلمة ساندر للبيع

المورد الكلي سحق equiptment المورد المملكة المتحدة

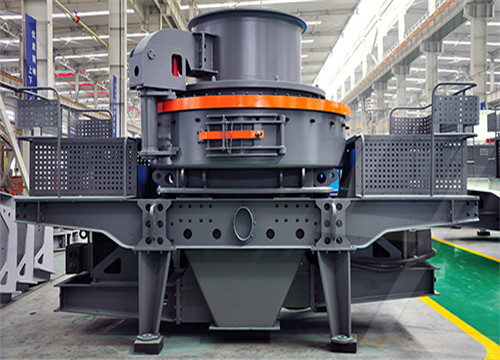

vsi محطم مخروط من cgm

الذهب تأثير التعدين محطم

مصنع الرمل مع مقابل

سنگ آهن مرطوب

كسارة حجر في حيدر أباد

آلات كسارة مخروط هيدروليكية الخرسانة في الخرطوم

الكوبالت الأرض آلات معالجة خام

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20