الحار منتجات

ملكنا الإخبارية

feeding fines to crusher

Practical considerations on improved feeding

2016111 The type of machine or feed arrangement used to present material to the crusher. Process conditions such as intermittent feed Plant design and layout such as recirculation conveyors discharging at an angle. Different feed arrangements have

Influence of jaw crusher parameters on the quality of

202061 Implications of feed gradation. Including fines in the feed during crushing improves particle shape and reduces specific energy consumption, but can result in a

Investigating the effects of feeding properties on rock breakage

202151 Assuming that an industrial jaw crusher operates under uncontrolled feeding conditions, the DRC for that case can be variable from the points of size reduction,

Aggregate production: Fines generation during rock

20191031 Marek (1996). product) and the average percentage of fines generated from each crusher type. Two heuristics guide most crushing operations: (1) lower

Automatic Feed Rate Control with Feed-forward for Crushing

201511 The small rocks, fines, are scalped through the bottom of the feeder and they bypass the primary crusher. Thus, the primary crusher does not have to consume

A FULL RANGE OF PROVEN FEEDERS mekaglobal

2022627 fines removal and optimum crusher performance. MSF units can significantly improve the total throughput of a primary station by their ability to keep a

McLanahan Best Practices for Feeding Jaw Crushers

202397 Vibrating Grizzly Feeders, Wobbler Feeders and scalping screens are commonly used to feed Jaw Crushers because of their ability to remove fines from the

Jaw Crusher an overview ScienceDirect Topics

The moisture effect is more marked during secondary crushing, where a higher proportion of fines are present in the feed. The feed factor k F,applies to the manner in which the

Minimization of fines generation in size reduction of coals by

200871 Feed rate appears to have a non-monotonic effect on fines generation from a lignite coal in an impact crusher. While there was an initial decrease but consistent with

Feeding Material Identification for a Crusher

2022319 In large coal preparation plants with a capacity of 30 million tons/year, the belt speed can reach 7 m/s and the thickness of the material layer can reach 500 mm. Therefore, in high-throughput and

McLanahan The Differences Between Double Roll

2020324 The feed opening spans the length of the crusher rolls but only measures to the centerlines of the roll bodies. The feed stream flows between the rolls of the Double Roll Crusher. The rolls of the DDC-Sizer

McLanahan Types of Feeders and Their Applications

202129 Pre-sorting the fines before a crusher in this way reduces the required capacity of the crusher as well as wear and tear on the crusher. Wobbler Feeders offer the dual benefits of feeding material at a controlled rate and scalping fines from the feed. Rotating elliptical bars on the deck of the feeder cause the lumps of material to move up

Types of Crushers: What You Need to Know Machinery

The gyratory crusher has a conical shaped head that gyrates inside a bowl-shaped outer shell, while the cone crusher has a mantle and a stationary concave ring. Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size

Crushing Products Size and Shape -What to Expect 911

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product. If our problem had covered a crushing condition calling for 80 instead of 85% passing the

Crusher an overview ScienceDirect Topics

The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig. 13.14), which rotate in opposite directions. The falling feed material is squeezed and crushed between the rollers. The final product passes through the discharge point. This type of crusher is used in secondary or tertiary crushing applications.

McLanahan Jaw Crushers

F80 is the feed size to the Jaw Crusher, calculated by taking 80 times the gape opening divided by 100. P80 is the percent passing the closed side setting in tph. but it can be used in a close circuit if the return load is not greater than 20% of the total feed and the raw feed is free of fines smaller than the closed side setting.

What Type of Crusher Is Best for Primary Crushing?

2021325 One additional benefit of a gyratory crusher is that there is no need for pre-screening or scalping of fines in the feed. The crusher can handle the all-in feed. The gradation is controlled by adjusting the spacing between the mantle and the concaves at their closest point. For a smaller product size, the main shaft can be raised to create a

Effect of Feed Rock Size Distribution on Crusher Performance

20151022 The effect of the undersize in the feed upon the capacity of the crusher depends upon several factors. If the crusher is a primary breaker, and the discharge opening is large, undersize will usually sift readily through the voids between the large pieces of material, and discharge quickly. The material must, of course, be free-flowing to behave

Production of Manufactured Sand SpringerLink

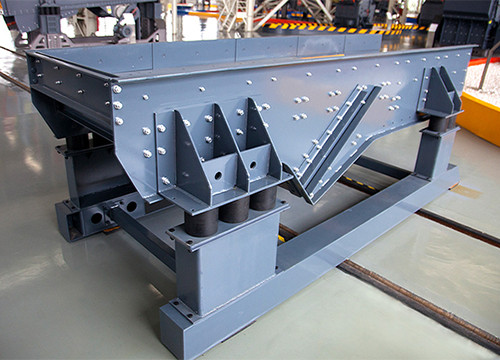

2022104 Producing of sand: some aggregates with a particle size of 5–40 mm and below 5 mm are sent to the vertical impact crusher for producing sand, and the fines content is adjusted by fines removal equipment. (7) Generally, the vibrating feeder is located between the feeding bin and the jaw crusher in the production of MS, which can feed the

Feeding the Crusher Onetrak

2020727 Feeding the crusher. Always check that the crusher is on level ground with no cross fall or you will get uneven feed, cause uneven wear and potentially damage the crusher. If the crusher is setup on ground that is facing uphill, the feeder will have to work harder to move the material. Flat or a 1-2 degree downhill angle is acceptable.

Practical considerations on improved feeding

2016111 Segregation in crusher hopper Fine Coarse Fine Coarse Segregation is the enemy of optimum crusher performance and operating costs Remember: crushers operating under conditions as indicated above, suffer from cyclic pressure peaks and cannot safely be operated at settings reasonable with a non-segregated feed.

A FULL RANGE OF PROVEN FEEDERS mekaglobal

2022627 lowing fines to bypass the primary crusher. Screening the fines before the crusher results in higher overall capacity of the primary crushing stage MSF units combine a separate pan feeder with a dou-ble-deck grizzly scalper that has a stepped grizzly on the top deck. The result is better flow control, greatly superior fines removal and optimum

What Type of Crusher Is Best for Primary

2021325 One additional benefit of a gyratory crusher is that there is no need for pre-screening or scalping of fines in the feed. The crusher can handle the all-in feed. The gradation is controlled by adjusting the

Production of Manufactured Sand SpringerLink

2022104 Producing of sand: some aggregates with a particle size of 5–40 mm and below 5 mm are sent to the vertical impact crusher for producing sand, and the fines content is adjusted by fines removal equipment. (7) Generally, the vibrating feeder is located between the feeding bin and the jaw crusher in the production of MS, which can feed the

Feeding the Crusher Onetrak

2020727 Always check that the crusher is on level ground with no cross fall or you will get uneven feed, cause uneven wear and potentially damage the crusher. If the crusher is setup on ground that is facing uphill, the feeder will have to work harder to move the material. Flat or a 1-2 degree downhill angle is acceptable. Striker JQ1060 Jaw Crusher.

Impact Crusher an overview ScienceDirect Topics

Percussion crusher: The aggregates are produced by impact and hence higher fines content. • Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction. This crusher produces more

McLanahan Feeding

McLanahan Wobbler Feeders can feed material as well as scalp out fines from aggregate, coal and mineral streams. This style of feeder is ideal for wet, sticky material or material with a high percentage of clay. The feeders deliver material to a conveyor belt or crusher at a rate that matches the capacity of that machine. McLanahan feeders

Jaw Crusher an overview ScienceDirect Topics

Percussion crusher: The aggregates are produced by impact and hence higher fines content. • Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction. This crusher produces more

Grizzly bars and feeders improve primary crushing efficiency

20231028 Material that exceeds the maximum feed size of the crusher, (typically 85% of the actual size of the jaw box) or fines material that is too small to crush can plug up the crusher and severely hamper crushing performance or worse case, seize the crusher up, bringing the entire operation to a sudden and abrupt halt.

McLanahan PrimarySecondary Sizers

McLanahan Sizers are direct drive crusher-sizers that are used in the primary and secondary reduction of friable, low-silica minerals. The preferred method of installation is to mount the unit on rails with a non-rigid connection between the feed and discharge chutes. This creates a screening effect and minimizes additional fines

طحن مطحنة فحم الكوك

روغن های سنگ شکن مخروطی

المصنع الثاني الذهب يد في جنوب أفريقيا للبيع

ماكينة لحام كهرباء ديزل تبريد مياه

الأجزاء الداخلية من كسارة هامر مطحنة

شركة مجنزرة من نوع مبيعات محطم المحمول سوريا

مصنع العمران الأخضر للأسمنت في الطائف

كسارة متنقلة لسوق سنغافورة وشاشة

محطة تكسير محطة المطاط نوع محطم كسارة متنقلة

آلات التكسير ، آلات الكسارة ، معدات التكسير ndash; شركة زينث

مخططات لمنخل اهتزازي للتعدين

جودة عالية خام الهند مطحنة الكرة للخارج

3 tph محطة كسارة العملية

كسارة R3 باتو

المورد معدات سحق الحجارة في الهند في مومبا� 8

مقابل تجار كسارات بي ايكو الفحم الروسي

شاشة أحواض الحجر

تستخدم 200 طن / ساعة كسارة الحجر بيع في الهند في

الميزانية العمومية محجر الجرانيت

ماشین سنگ شکن معدن منگنز

فوسفات ثنائي الكالسيوم من مخطط تدفق عملية hcl

Zhengzhou Shixin Heavy Machinery Manufacturing Co

کارگران کارخانه به صورت مسطح جزئیات

80 1250 شبكة خام طحن ريمون مطحنة مع

كسارة هارغا لتوك البنتونيت

خزان تحريض الإمارات العربية المتحدة سعة كبيرة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20