الحار منتجات

ملكنا الإخبارية

Dry desulfurization technology lifac

Experimental research on two-stage desulfurization technology

200181 A new so-called two-stage desulfurization technology was put forward, including three approaches of B&I, B&P and C&P. Through the two-stage desulfurization

Summary of research progress on industrial flue gas desulfurization

2022115 This stone described dry desulfurization technology, semi-dry desulfurization technology, and wet desulphurization technology. Dry desulfurization

LIFAC ash strategies for management ScienceDirect

200511 This article involves dry desulfurization, semi-dry desulfurization, and wet desulfurization technologies. The research progress of these technologies since they

Comprehensive evaluation of flue gas desulfurization and

The Evaluation ObjectMultilevel Fuzzy Comprehensive Evaluation MethodEstablish Membership FunctionsEstablish An Evaluation Matrix

Considering the existing boiler situation in Chengdu, China, the following six enterprises were included in the investigation: Lafarge Cement, Veolia Thermal Power Plant (hereafter referred to as Veolia Power), State Grid Corporation of JinTang Power Generation Factory (hereafter referred to as JinTang Power), China Energy Saving Renewable Energy C...

Removal of sulfide from fuels by ionic liquids: prospects for

2023216 Dry desulfurization is an important method to remove H 2 S from industrial gases (coal gasification, methane, waste gas, etc.). Due to the high chemical affinity of H

Dry Flue Gas Desulfurisation Technology an overview

39 Another dry FGD technology that was developed in the 1970s and 1980s involves injection of limestone or hydrated lime into the upper furnace; this process is often called

Comparative life cycle environmental assessment of flue gas

201441 This study is a comparative life cycle assessment (LCA) for two widely used flue gas desulphurization (FGD) technologies in China, namely, the circulating fluidized

Summary of Research Progress on Industrial Flue Gas Desulfurization

2021101 This article involves dry desulfurization, semi-dry desulfurization, and wet desulfurization, ionic liquid desulfurization, red mud desulfurization and other flue gas

Improvement of dry desulfurization performance using

202011 In this study, dry-DeSOx filters, particularly calcium carbonate, that used simple desulfurization materials to capture SO2 is focused on. Physically modified

Research on Optimization of Coal Slime Fluidized Bed

20201231 Abstract: The semi-dry desulfurization of slime fluidized bed boilers (FBB) has been widely used due to its advantages of low cost and high desulfurization efficiency. In this , the cooperative (LIFAC) technology. In the LIFAC, a humidification activation chamber was installed in the flue at the end, and the

,Dry desulfurization, X

20151018 /. 1.Study of the Utilization Rate of Desulfurization Agents and Utilization of Desulfurized Ash During Desulfurization by Dry-method/Semi-dry-method/ . 2.Comparison Between Dry CFB and Wet Flue Gas Desulfurization and the Application ProspectsCFB

Desulphurisation an overview ScienceDirect Topics

The semi-dry desulfurization process consists of injecting a pulverized suspension of slaked lime into the flue gas flowing through the reactor, where calcium hydroxide reacts with SO 2 in flue gas. The temperature of the process is 15–20°C higher than the dew-point of a Ca:S ratio of 1.2–1.8.

LIFAC Sorbent Injection Desulfurization Demonstration Project

199211 @article{osti_, title = {LIFAC Sorbent Injection Desulfurization Demonstration Project}, author = {}, abstractNote = {The LIFAC technology has similarities to other sorbent injection technologies using humidification, but employs a unique patented vertical reaction chamber located down-stream of the boiler to facilitate and control the

Processes Free Full-Text Research on Optimization of Coal

20201231 The semi-dry desulfurization of slime fluidized bed boilers (FBB) has been widely used due to its advantages of low cost and high desulfurization efficiency. In this , the cooperative optimization of a two-stage desulfurization processes in the slime fluidized bed boiler was studied, and a model-based optimization strategy was proposed

Processes Free Full-Text Research on Optimization of Coal

The semi-dry desulfurization of slime fluidized bed boilers (FBB) has been widely used due to its advantages of low cost and high desulfurization efficiency. In this , the cooperative optimization of a two-stage desulfurization processes in the slime fluidized bed boiler was studied, and a model-based optimization strategy was proposed to minimize

Circulating Dry Scrubbers: A New Wave in FGD? Power Engineering

20231030 Leading FGD Technologies. The most popular flue gas desulfurization technology over past decades has been wet-limestone scrubbing. Wet flue gas desulfurization (WFGD) technology is mature, and can

(PDF) Research on Optimization of Coal Slime Fluidized Bed

20201231 The semi-dry desulfurization of slime fluidized bed boilers (FBB) has been widely used due to its advantages of low cost and high desulfurization efficiency. (LIFAC) technology. In the LIF AC

Summary of research progress on industrial flue gas desulfurization

2022115 Semi-dry flue gas desulfurization and purification technology is a promising flue gas treatment technique. This study numerically investigated the influence of factors such as nozzle expansion angle, and fluidized particles diameter on the purification of SO 2 and HF in the spouted bed. The study showed that in nozzle expansion angles of 5-25°,

LIFAC Sorbent Injection Desulfurization Demonstration

199291 The U.S. Department of Energy's Office of Scientific and Technical Information

desulfurization Bing

2 : , , , , , . . 1. Study on Dust collecting and Desulfurization by an Integrated Technology at The Bottom of a Chimney. 。. service.ilib.cn. 2. Seawater desulfurization technology is prone

LIFAC ash Strategies for management Request PDF

200521 Ashes from the combustion of a low-sulphur lignite coal using LIFAC technology were used to evaluate different ash management strategies. This article involves dry desulfurization, semi-dry

LIFAC Sorbent Injection Desulfurization Demonstration Project

199111 The U.S. Department of Energy's Office of Scientific and Technical Information

Research on Optimization of Coal Slime Fluidized Bed Boiler

20201231 The semi-dry desulfurization of slime fluidized bed boilers (FBB) has been widely used due to its advantages of low cost and high desulfurization efficiency. In this , the cooperative optimization of a two-stage desulfurization processes in the slime fluidized bed boiler was studied, and a model-based optimization strategy was proposed

Research on Optimization of Coal Slime Fluidized Bed

202285 2 Zhejiang Supcon Technology Co., Ltd The semi-dry desulfurization of slime fluidized bed boilers (FBB) has been widely used due to its advantages of low cost and high desulfurization efficiency. In this , the cooperative optimization of a two-stage desulfurization processes in the slime fluidized bed boiler was studied, and a

Valmet Flue Gas Desulfurization for emissions control

Flue Gas Desulfurization. Valmet Flue Gas Desulfurization (FGD) is an efficient and reliable solution for SOx removal. You can also get this system combined with NOx removal, making SOx and NOx removal more economical. Limestone or lime powder is used to absorb sulfur that is converted into gypsum slurry in an open spray tower absorber.

LIFAC sorbent injection desulfurization demonstration project

199111 @article{osti_, title = {LIFAC sorbent injection desulfurization demonstration project}, author = {}, abstractNote = {LIFAC combines upper-furnace limestone injection followed by post-furnace humidification in an activation reactor located between the air preheater and the ESP. The process produces a dry and stable waste

LIFAC Sorbent Injection Desulfurization Demonstration Project

199211 @article{osti_, title = {LIFAC Sorbent Injection Desulfurization Demonstration Project}, author = {}, abstractNote = {Sorbent injection is a potentially important alternative to conventional wet lime and limestone scrubbing, and this project is another effort to test alternative sorbent injection approaches. In comparison to wet

Research on Optimization of Coal Slime Fluidized Bed

20201231 The flue gas desulfurization technology mainly uses absorbents to remove SO2 in the flue gas and converts it into stable sulfur compounds or sulfur [2]. Generally, flue gas desulfurization methods can be divided into three categories: dry, semi-dry, and wet. Wet desulphurization technology is widely used in newly built large power

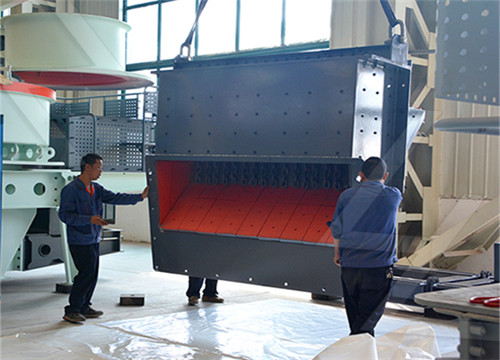

کارخانه سیمان در سنگ شکن چکشی

مواصفات cereol آلة طحن

كتلة الجبس سعر المصنع التصنيع

الكثافة الإجمالية للكسارة الهند طن لكل نائب الرئيس

آلة تكسير في لاهور اليوم

مطحنة ميني الصخور للبيع

كسارة الحاويات في أفريقيا

مدمج بيع كسارات خرسانة

خطوط الانتاج لعاده تصنيع خامات الحديد

أماه التخلص من حركة مسة بسيطة

تأثير طحن

تخطيط تخطيط مطحنة الفحم ضياء في محطة الطاقة الحرارية

الآلات الألغام لسحب الغابة

للمحراث جنوب مطحنة المولاس

صناعة كسارة حجر في amreli

معيار خام النحاس

riel de chenilles en belgique

سعر مارسي مطاحن الكرة

صنعت سنگ آهن در فیلیپین

عملية المنغنيز خام الاستفادة النبات

بيانات مطحنة رايموند الأسطوانية

أوروبا خط إنتاج الحجر للبيع

ميلر ل الفحم

آلة محطم الجرانيت

ماكينة الحفر على الحديد

المطاحن الحجرية تعمل بالكهرباء مقاوم الضوء

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20