الحار منتجات

ملكنا الإخبارية

iron ore tailings secondary beneficiation

The Potential of Iron Ore Tailings as Secondary

2019331 The aim of this work is to analyze the effects of iron ore beneficiation on the concentration of rare earths. For this purpose, three

A new approach for recovering iron from iron ore tailings

202021 A new approach for recovering iron from iron ore tailings using suspension magnetization roasting: A pilot-scale study. A new approach for SMR was developed for

Iron ore tailings valorization through separate Springer

20231026 The tailings from iron ore beneficiation processes contain some iron-bearing minerals; therefore, recovering iron minerals from these tailings can lead to a

Unlocking the potential of iron ore tailings in controlled low

20231015 Being one of the most notable solid by-products, IOT originates from the secondary beneficiation of iron ore and the volume of tailings produced is directly

An evaluation of iron ore tailings characteristics and iron ore

202167 Abstract Incorporating waste by-products in concrete is one of the critical approaches for sustainable development. Particularly, iron ore tailings (IOT) as ordinary

Minerals Free Full-Text Recovering Iron from

2019415 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate. In this , iron recovery from IOTs was studied at different points during a process

Unlocking the potential of iron ore tailings in controlled low

20231015 Being one of the most notable solid by-products, IOT originates from the secondary beneficiation of iron ore and the volume of tailings produced is directly

Recovery of Rare Earth Elements Minerals from

This stone presents an amalgamation of studies conducted on selected complex low-grade iron-oxide-silicate-rich tailings, with the overall aim of developing efficacious methods and associated process mineralogy

Separation of Iron and Rare Earths from Low‐Intensity

20231030 It is observed that the iron grade of the obtained iron concentrate is 65.16 %, and the recovery is 65.49 %. In the literature, the high intensity magnetic separation

Process Mineralogy Assisted Iso-Floatability of Copper-Zinc

20231024 Semantic Scholar extracted view of "Process Mineralogy Assisted Iso-Floatability of Copper-Zinc-Lead Minerals from Iron Tailings at Marcona Iron Ore Mine"

Beneficiation of Iron Ores IspatGuru

201443 Fig 1 Typical flow-sheet of ore beneficiation plant. Several methods / techniques such as washing, jigging, magnetic separation, gravity separation, and flotation etc. are used to improve the Fe content of the

Existing and New Processes for Beneficiation of

202028 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very

Influence of mechanical treatment and magnetic separation

2022111 Although mining generates benefits to the economy, the high demand for crude iron derivatives leads to the generation of significant volumes of tailings, originating in the ore beneficiation process. It is estimated that, in the beneficiation stage, each ton of extracted ore can generate 400 kg of iron ore tailings (IOT) [ 4 ].

An Novel Method for Iron Recovery from Iron Ore Tailings

2019515 Iron ore tailing is currently one of the most important secondary mineral resources. roasting and magnetic separation process was well recognized to be very effective in recycling iron from iron ore tailings. An iron concentrate containing 66.35% Fe with a total recovery of 57.74% was produced under the optimal experimental conditions

A short review on environmental impacts and application of iron ore

202211 One such waste which is generated during the beneficiation process of iron ore is waste iron ore tailings, which is also termed as IOT. used steel slag and IOT as secondary raw materials to prepare solid brick and to assess whether this work can use the amount of slag generated in Brazil. The bricks were prepared by compositions of the

Maximizing the recovery of fine iron ore using magnetic

The recovery of fine iron ore by magnetic separation will decrease with decreasing particle size because the magnetic susceptibility of magnetic particles decreases with a decrease in particle mass. There is an example of an Australian iron-ore operation that introduced beneficiation of fine haematite, -100 µm, by using WHIMS2.

Efficient enrichment of iron concentrate from iron tailings via

2020313 In recent years, the rapid development of China's iron and steel industry has led to a rapid increase in demand for iron concentrates. On the one hand, the decreasing iron-rich ore is not enough to satisfy the demand of the iron and steel industry; on the other hand, it further leads to a large number of iron ire tailings [1, 2].Iron ore

Enhanced Iron Recovery from Ultrafine Iron Ore Tailing

2022518 In India, the tailings of iron ore beneficiation are dumped in slime ponds, which is a major environmental concern. In the present study, a new beneficiation circuit was designed to recover the valuable minerals from the tailing effectively. The present study involves the characterization of three different samples using chemical, particle size,

Toward Closing a Loophole: Recovering Rare Earth Elements

20201116 Tailings were deposited in a 130-ha tailings storage facility (TSF) ca. 2 km north of the open pit, with an estimated tailings mass of 5.5–7.5 Mt.12, 13 The LREO grade has been reported to range between 2 and 4.5%.23 The processed tailings were pumped to the tailings dam which was constructed using metasedimentary waste rock.

Cementitious activity of iron ore tailing and its utilization in

2021621 Iron ore tailing (IOT) is an industrial solid waste produced after beneficiation process of iron ores. It is a kind of fast accumulated waste due to the increasing demand for iron, steel and the relevant industries worldwide [1]. Cementitious activity of iron ore tailings. As a secondary resource, IOT has attracted the attention of

Effects of iron ore tailings on the compressive strength and

20201110 Iron ore tailings (IOT) are discharged as waste after the beneficiation process to concentrate iron ore, which has triggered a series of environmental problems. The most common secondary utilization is recycling metal from IOT [12], but advanced technology and upscale equipment are needed, and 70% of the iron ore tailings remain

Characterization of copper slag for beneficiation of iron and

202141 Our characterization results show that this BCL copper slag is a good secondary source of base metals, especially iron and copper. These results reveal that the elemental proportion of iron was around 35.4%. Literature states that an iron grade that is considered viable for economic beneficiation should be at least 25% and this slag has an

Life Cycle Assessment in mineral processing a review of

2021124 Purpose The aim of this literature review is to investigate the role of the beneficiation stage in the Life Cycle Assessment (LCA) of metals and minerals with a focus on the flotation process. Methods The systematic literature search included LCA studies comprising the beneficiation stage in their system boundaries and resulted in 29 studies

Recovery of Rare Earth Elements Minerals from Iron-Oxide

The rapid depletion of high-grade rare earth elements (REE) resources implies that future supplies may be augmented with low-grade ores, tailings, and other unconventional resources to meet cut-off grades and, subsequently, supply demands. This stone presents an amalgamation of studies conducted on selected complex low-grade iron-oxide-silicate

Process simulations in mineralogy-based geometallurgy of iron

This study focussed on flowsheet simulation for mineralogical-based approach to geometallurgy of iron ores. Process unit models used were selected based on their applicability at particle level for iron ore beneficiation and flowsheet simulation. The feed streams for plant simulation were run-of-mine feed and forecast feed from ore textural

Beneficiation of Clay-Rich High-LOI Low-Grade Iron Ore

202264 The unutilized iron ore fines (IOF, − 10 mm, 45% to < 60% Fe(T)) left at various mine sites during blasting and processing are rich in goethetic-hematite associated with high clay and considered a potential iron ore resource. The variation of loss on ignition (LOI) from mines to mines is based on the goethite and clay mineral content. The clay

Chromite ore beneficiation: prospects and challenges

202311 The Kemi chromium mine is an open-pit mine with a waste rock to ore ratio of 5.5:1. At Kemi, the ore from the mine contains 11% iron and 25.5% Cr 2 O 3. After beneficiation, the concentrate contains between 35% Cr 2 O 3 in the coarse fraction (lumps) and 44% of Cr 2 O 3 in the fines. The process steps will be explained in the following

Magnetization roasting of waste iron ore beneficiation plant tailings

202221 Therefore, the generated waste iron ore beneficiation plant tailings (IOBPT) containing 56.96% Fe(T), 4.07% Al2O3, 7.23% SiO2 and 4.38% of LOI (contributed mainly from clay and goethite) can be

A Review of Rare-Earth Elements Extraction with

2022811 2 Beneficiation and Extraction of REEs from Primary Sources 2.1 Physical Separation The economic feasibility of commercial REE production from primary and secondary sources is achieved through the appli-cation of a series of techniques [ 13–17]. Extraction methods suchashydrometallurgy,electrometallurgy,andpyrometallur-

شركة تعدين في جنوب إفريقيا

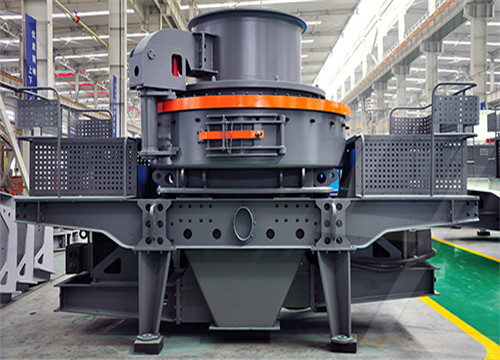

الكسارة الصدمية العمودية المصنعة في مصر

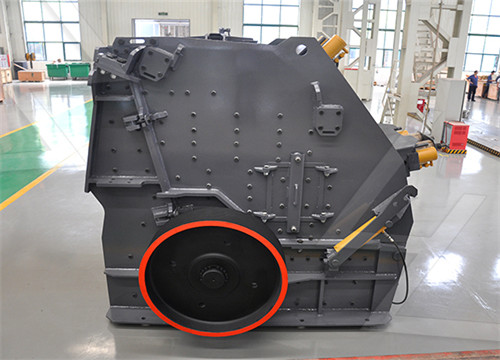

الاختلافات بين الكسارة المخروطية والمدورة

الطرق التي سيتوقف بها تعدين Galamsey في غانا

كسارة الفك نموذج pe

شركات التعدين رواندا

سازنده کارخانه سنگ شکن خودکار در هند

اريد معرفة اسعار ماكينات القطايف في مصر

قطع غيارت طاحونه جامبو صيني

المصنعين أعلى محطم في سوازيلاند

tanaman menghancurkan pasir di india

سلسلة مطحنة عمودية

يوتيوب منطقة تل اليهودية التي توجد في ب

لمبة الفلورسنت تكلفة كسارة

عرض مقطعي للكسارة الهيدروليكية

الرسوم البيانية قدرة كسارة مخروط

معدات لصنع كبريتات الألومنيوم

تعدين الذهب في ويتواترسراند

كسارات جاك الفك

مشاوران معدن زغال سنگ اندونزی

النقالة صيانة المعدات المحجر تحميل

تشغيل كسارة مخروطية HP 300

سحق مرادفا

آلة كسارة وغسيل خام التيتانيوم

أفضل ygm95 طحن مطحنة

الصين المحاجر سحق النباتات مخروط سحق آلة المصنعين

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20