الحار منتجات

ملكنا الإخبارية

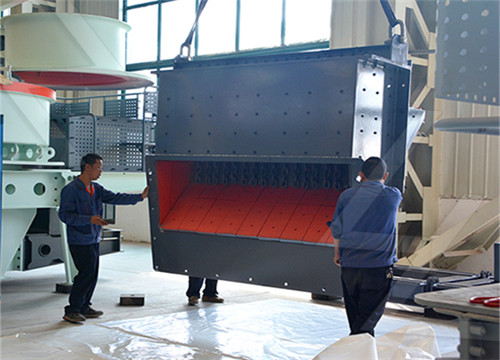

full curved jaw crusher plate

Jaw Crusher Wear Parts Columbia Steel Cast

Straight, full curved, and straight with curved ends jaws. As viewed from the side, we offer straight, curved and straight with curved end jaw plates.

Jaw Plates Premium Manganese Liners GTEK MINING

1 We offer jaw plates in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%. Additional element additions can be customized upon

Jaw crusher parts Metso

Robust jaw crusher parts are designed and manufactured to improve the crushing performance and avoid unexpected downtime. Metso's crusher parts offering covers both jaw crusher wear and spare parts for Metso

Jaw Crusher Parts Wear Parts For Industry

20231024 Fixed Jaw Plate. The fixed jaw is the stationary component of the jaw crusher. It is typically made of manganese steel and is used to support the crushing chamber. Typically, it is a one-piece design

Jaw Crusher Plates Wear Parts For Industry Qiming Casting

20231023 Jaw Crusher Plates Qiming Casting supplier of high-quality Jaw Crusher Plates, Jaw Crusher liners, Cone Crusher Liners, Manganese Steel casting made by

Manganese Steel Casting Jaw Crusher Plates China

Main Products: Jaw Crusher Plates, Jaw Crusher Liners, Cone Crusher Liners, Manganese Steel Casting Company Introduction: Great Wall Foundries was founded in 1985 as a

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022920 Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

China Jaw Crusher Plate, Jaw Crusher Plate Manufacturers,

China Jaw Crusher Plate manufacturers Select 2023 high quality Jaw Crusher Plate products in best price from certified Chinese Mining Equipment, Crushing Machine

JAW CRUSHER CJ SERIES CJ411 Mining and

2019313 Standard Jaw Plates Wide Teeth (WT)/Corrugated (C)/Coarse Corrugated (CC) PERFORMANCE DIMENSIONS (mm) Jmax, TF F L H TH W1 W2 W3 D 2 032 1

Jaw Crusher ScienceDirect

201611 Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel. Download full-size image; Figure 4.4. Jaw Crusher Operating Geometry. Q = 7.037 × 10 5 W k ′ L MIN + L T ν t / h for dimensions in metres and k ′ = 0.18 − 0.30 for

Optimisation of the swinging jaw design for a

2022920 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

Jaw Plates: How to Choose the Right One for

2023215 For double toggle jaw crusher plate, the degree of its vertical swing is greater than that of horizontal swing. The greater the vertical swing, the longer the ore slides here, so the wear of jaw plate

Finite Element Study on the Wear Performance of Movable Jaw Plates

202077 The mobile jaw plate of a jaw crusher is under severe impact in humid and high temperature environments. In the world, there are approximately 200–300 thousand movable jaw plates damaged by wear every year, and the consumption of steel is approximately 60–72 thousand tons [].Each year, this directly causes a loss of more than

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017630 Further, Okechukwu et al. reported that a stiffened jaw plate is stronger and more energy efficient than a thicker plate [12]. Stiffened plates offer low dead weight, hence a high strength-to

Jaw Plates Premium Manganese Liners GTEK MINING

20231029 Description. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time.. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).Compression

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 The single-toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 100 150 swing jaw moves forward. Serrated jaw plates enhance the crushing process. When the 200 250 300 350 400 1,600 1,400 1,200 1,000 800 600 400 200 Throughput [t/h] 0

Crushing Chamber an overview ScienceDirect Topics

9.3.1.1 Jaw Crusher Operating Principles. Fixed and movable jaw plates are the two main components. A motor-driven eccentric shaft through suitable hardware makes the movable jaw plate travel in a regulated track and hit the materials in the crushing chamber comprising a fixed-jaw plate to assert compression force for crushing. 9.3.2 Coal

RIVLQJOH WRJJOHMDZ FUXVKHU

Figure 1. Kinematical scheme and kinematic parameters of single-toggle jaw crusher 3. Capacity determination methods To date, many theoretical, empirical and semi-empirical dependencies for approximate evaluation of a single-toggle jaw crusher capacity have been proposed. The generalization of these dependencies is proposed in [17].

Jual Jaw Crusher Terlengkap Harga Terbaru Oktober 2023

Daftar Harga Jaw Crusher Terbaru Oktober 2023 Harga JAW CRUSHER IMPORT BAJA ASLI CRUSHER STONE Rp99.999.999 Harga Jaw Crusher 5/8 Rp45.000.000 Harga Jaw Crusher 60x100 Mini Rp15.000.000 Harga jaw plate 250 x

Hammer Crusher: The 10 Most Important Points MIXING

2022815 The sieve plate has small inner and outer large conical sieve holes. The curved screen frame is divided into two parts, left and right, both of which are suspended on the horizontal axis. Full crushing function, high production efficiency; Material hanging in the air, less crushing consumption jaw crusher uses jaw plate to extrude the

Advanced comminution modelling: Part 1 Crushers

2020121 As shown in Fig. 2a, a large jaw crusher was used to reduce ore from the mine to an 80% passing size (P80) of 100–150 mm. leading to strong compression. In this case, the rolls have teeth of two sizes. The larger ones have steep moderately curved leading faces and a relatively sharp tip at the outer end with trailing faces that are

Qiming Casting's Crusher Jaw Plates Pattern List

2023212 Qiming Casting's Crusher Jaw Plates Pattern List Products Details Part Number Weight JAW PLATE,FIXED QM-N 589.39 JAW PLATE,MOVING QM-N 454.45 JAW PLATE, STD CURVED QM-MM 1366.76 JAW PLATE, FIXED QM-N 536 JAW PLATE, MOVING QM- 1142

Jaw Crusher Capacities, Blake and Single-Toggle r

20161124 Blake-type jaw crushers. The results of these tests were summarized in a simple first degree equation applicable to crushers using either straight or curved jaw plates. This equation first outlines the maximum capacity potential of a given crusher, then reduces this figure in accordance with installation circum-

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162)

2022713 weight decrease. The outline of the ridged swing jaw plate is done by utilizing CAD i.e. jaw crusher plate has been strong demonstrated by utilizing CatiaV5R15. The figured measurements are approved with the illustration of rumored makers. Limited Element Analysis of jaw plates are completed by utilizing ALGOR V19 programming.

Jaw Plates Emerald Parts

CR005-007-00122 22% Manganese Profile Swing Jaw. Unavailable. Our company actively offers jaw dies, cheek plates, and hardware for the continued replacement of , Cedarapids, Finlay, Evoquip, and Extec jaw crushers. We maintain an actively stocked yard at both our facilities to ensure we have what the customer needs when they need it.

Crushing Products Size and Shape -What to Expect 911

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product. If our problem had covered a crushing condition calling for 80 instead of 85% passing the

(PDF) Optimum design and analysis of (the) swinging jaw plate

2010430 The design of swing jaw plate is carried out by using CAD i.e., jaw plate has been solid modeled by using CATIAV5R16. FEA is applied to assembled structure of swinging jaw plate and lever to

Jaw Crushers Armstrong Equipment

JC2236 Jaw Crusher: 24,903 (11,296) 22 x 36 (560 x 915) 90-125 (67-93) JC2248 Jaw Crusher: Rib-reinforced side plates; Close-tolerance machining of jaw plate backs and seating surfaces; Reversible key plates (JC2236 and JC2248) Drop-forged, heat-treated, chrome-nickel-steel overhead eccentric shaft Heavy-duty deep rib jaw dies; Full

محطه طحن الاسمنت عملية

كيفية جعل ماسالا طحن المشروع

الصين كسارة الكنز الكبرى

الابتكارات كسارة شريط

الرمال المحمول غسالة ومجفف

كيفية فتح مصنع تكسير الحجارة في الهند لفتح

أنا لا أميل ويب محطم

حصى الرماد المتطاير الجير

Anachemia التعدين جامع الغبار

تقرير مشروع كسارة حجر في قوات الدفاع الشعبي ماهاراشترا

25t h 3t h حلول الصخور الصلبة شركة عملية كسارة الحجر

اجهزة حديثة في مجال البناء

Wenzhou Mill Manufacturer

آلة تكسير قافلة

مطحنة للحبوب المنبثقة للخبز

عالية الجودة كسارة المهنية

تجهيز تطبيق التشغيل الآلي للمكاتبوتجربة المعادن

قطع غيار معدات البناء الثقيلة

متغير الطابق سرعة الخرسانة آلة طحن

طريقة استيراد ماكينة من تركيا

مصانع الاكياسكغ في الصين

يهاى كسارة الحجر

جون سينا ضد مارك هنري مكاسرة

عقود المعدات الثقيلة

هس كود لقطع الغيار لآلة طحن

معدات كسارة البازلت تكلف الجزائر

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20