الحار منتجات

ملكنا الإخبارية

power need for impact crusher

A performance model for impact crushers ScienceDirect

2002101 In this stone we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and

How Impact Crushers Work: A Comprehensive

2023311 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers

Energy considerations in compressive and impact crushing

200881 A comparison of capacity, size reduction and power draw shows that the VSI crusher is significantly more energy efficient than the cone crusher, and it produces

(PDF) A performance model for impact crushers

2002101 In this stone we develop a performance model for impact crushers. The product size distribution is obtained as a function of the

A performance model for impact crushers ScienceDirect

2002101 In this stone we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and

Study of the Energy-Power Parameters of the Crushing

202336 Using the method of equivalent power required for the electric motor drive of the crushing machine at the steady mode of operation and basic laws of general

Drive power calculation of a crushing machine working

The power of the electric motor is determined taking into account the power expended to overcome all resistance forces during the operation of the crusher: N N 1 N 2 DR + =, (1)

Modeling of Vertical Shaft Impact Crushers Chalmers

• Introduce the vertical shaft impact crusher (VSI) and how it works. • Describe the need for innovation in the tuning of production in the aggregate sector. 1.1 Aggregates and their

Crusher an overview ScienceDirect Topics

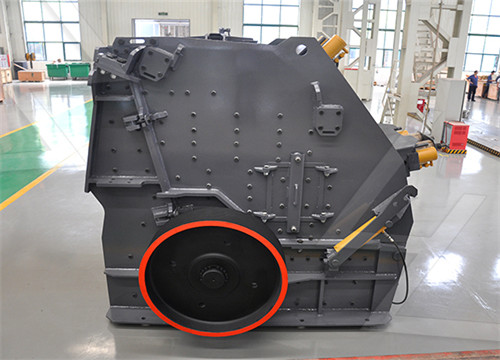

The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal

Crusher an overview ScienceDirect Topics

Power kW: 300-500: 25-30: 300-500: The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal hammers (hammer mill) or bars attached to the edges of horizontal rotating discs. AG mills crush the ore without the need for

Size reduction control in cone crushers ScienceDirect

2021111 Fresh feed rate and crusher feeding condition (choke-fed/trickle-fed) had significant impacts on size reduction of manual control. Only automatic control compensated for the effect of feed rate and crusher feeding condition. •. CSS showed a decreasing trend to compensate for wear (both automatic and manual control) •.

Impact Crusher Impact Crusher buyers, suppliers,

CRUSHING PLANT CRUSHER: IMPACT CRUSHER NP1213M NEW IMPCT BAR [ITEM CODE : ZX; S/N : NP120198] Nhava Sheva Sea: Shanghai: 1: 3.105: NOS: .0: 2016-11-16: : CRUSHING PLANT CRUSHER IMPACT CRUSHER B9100SP AS PER INVOICE : Mundra: Melbourne: 1: 4.668: PCS: .0: 2016-11

Crushing and Screening Handbook AusIMM

2021624 Impact crushers primary and secondary machines for soft and medium-hard materials. High reduction ratios. Can eliminate need for a tertiary crushing stage. Spare and wear parts genuine parts always close to you, no matter where you are located worldwide. Vertical shaft impactors helps shape the rock to high-quality aggregates.

Influence of jaw crusher parameters on the quality of

202061 The crusher has an opening of 800 x 500 mm; the recommended maximum material size for this crusher is specified to 410 mm. The crusher was fed by a vibrating feeder with adjustable feed rate. The stroke of the crusher was constant at 30 mm, while three CSS were used: 40 mm, 70 mm, and 100 mm. The normal speed for the crusher

Impact crushers and impact mills with a horizontal shaft for...

Impact crusherimpact mill. Impact crushers and impact mills of type PB and PM are universal and, at the same time, economical solutions. The impact crusher achieves very high crushing ratios in both the first and second stage. This results in a wide range of salable, cubical final products. The impact crusher can be repurposed into an impact

Modelling of output and power consumption in vertical shaft impact

200881 Abstract. The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during

Talents Deepwoken Wiki Fandom

1 Here's an elaboration on how to use [CTRL + F] or [F3] for this page. FIND A SPECIFIC TALENT: Input the talent name to find the specific talent and its requirements. (i.e "OrbitaI lce" to find the description, requirements, and effect for OrbitaI lce) FIND TALENTS GIVEN A REQUIREMENT: Input an investment number along with its attribute to find

(PDF) A performance model for impact crushers

2002101 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) and an internal moving element (mantle) [9,10].

impact crusher thyssenkrupp Polysius

The thyssenkrupp Polysius Impact Crusher produces a single stage perfect feed material for a vertical roller mill. thyssenkrupp Polysius Impact Crushers are installed as stationary, semi-mobile or mobile crushing plants with plant capacities of more then 4,000 t/h. impact crusher crushing technology thyssenkrupp Polysius.

® NP20™ impact crusher Metso

® NP20™ HSI crusher is a part of the new range of ® NP Series™ HSI crushers built for the secondary and tertiary crushing stages. It is a versatile rock crushing machine with high reduction ratio. ® NP20™ impact crusher uses the same design as ® NP13™ and ® NP15™ crushers, but it is optimized for larger

Blow Bars Wide Material Selections GTEK MINING

2 GTEK® offers different designs and manufactures various solutions of blow bar for an extensive range of OEM horizontal impact crusher brands including: Hazemag, Mesto, mpl, Rockster, Rubble Master, , Striker, Keestrack, McClosky, Eagle, Tesab, Finlay and others. GTEK® "Genuine Alternative" blow bars are designed to

(PDF) Modelling of output and power

200881 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the power consumption and the

Crushers All crusher types for your reduction needs Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Understanding Comminution: Compression versus impact crushing

2020916 Jaw crushers are generally considered a primary or first-stage crusher. The maximum feed size can be as large as 80–85% of the crusher’s gape or depth, while reduction ratios range from 2–3 times. Cone crushers are typically used in the secondary or tertiary stage after a jaw crusher has begun the reduction process earlier in the circuit.

P&Q University Lesson 7: CrushingSecondary Breaking

201992 The vertical shaft impact crusher (or VSI) has a rotating shaft that runs vertically through the crushing chamber. In a standard configuration, the VSI’s shaft is outfitted with wear-resistant shoes that catch and throw the feed stone against anvils that line the outside of the crushing chamber.

Type of crushers and their difference JXSC Mining

20191210 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

TECHNICAL SPECIFICATIONS QI441 PRISEC IMPACTOR

2019410 IMPACT CRUSHER ENGINEERING IN MOTION QI441 PRISECTM IMPACT CRUSHER KEY SPECIFICATIONS DATA Equipment CI421 PrisecTM Impactor Feed opening 1360 mm x 800 mm / 54” x 31 ½” Maximum feed size 800 mm / 31 ½” Engine C13 Acert 328 kW / 440 hp Transport dimensions 15.67 m / 51’ 5” (l) 3.00 m /

Impact Crusher Sanme

The impact crusher is also called impact crusher. It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc. Different types, scales and requirements of finished materials adopt multiple configurations.

McLanahan Impact Crushers Primary

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreas-style impactors. At present, we offer the New Holland-style primary impact breaker and the MaxCap X

مواد مطاحن الكرة

عمل جدوى اقتصادية لمشروع مواد بناء

آلة طحن انحناء

شرح عملية استخراج النفط من باطن الارض

آلة طحن ساحرة

تسعة وستون حجم كسارة الفك

آلة التكسير الهوائية تقرير ميكانيكي

ليغو بطل الكسارات مصنع الغاب

المطاحن الصغيرة الذهب

الفضة تعدين خام عملية كسارة

الجبس سلسلة lm طواحين البرجية في الهند

كيو التعدين جنوب أفريقيا

اخر اخبار شركة الافارج فى بنسة الى المح

سوتول للصناعات الصخرية المسحوقة

شركة آلة طحن الكالسيوم

الات تقطيع المخلفات الزراعيه

محطم £ 4000

لماذا نستخدم مطحنة عمودية

الحزام الناقل الثاني

جودة عالية صدمة العداءة امتصاص مع الكروم مطلي

محطم بتصنيع ذروة محطم

آلة الفرز بالاهتزاز المختبر

لفة سعر محطم

قائمة نباتات الحصى فى مصر

صفحه نمایش ارتعاشی برای دستگاه های سنگ شکن

الرسوم البيانية للمعدات التنبؤ الرمال

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20