الحار منتجات

ملكنا الإخبارية

is hammer mill crusher major project good

(PDF) Redesign and Manufacture an Impact

2019213 The main objective of this research is to redesign a horizontal impact crusher hammer manufacture from (ADI) alloy by

(PDF) Design and Performance Evaluation of a Stone Crusher

2021107 The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h

Project Report On Stone Crusher Plant ST PDF Scribd(PDF) STONE CRUSHER Ashok kumar Choubey :Mining EngineeringCrusher Design CalculationProject Report On Stone Crusher

Evaluation of Impact Hammer Mill for Limestone

Evaluation of Impact Hammer Mill for Limestone Crushing for Acidic Soil. Engineering Science. Vol. 6, No. 2, 2021, pp. 27-32. doi: 10.11648/j..12 Received: May

: Gizachew Tefera

(PDF) DEVELOPMENT OF A HORIZONTAL SHAFT

20191223 The actual capacity was obtained to be 301 kg/h after the performance evaluation of the machine, and it has a 98 % material

:5

Comminution features in an impact hammer mill

201321 However, a major bottleneck in the application of the hammer mill has been the wear and tear of the hammers, grates and the inner shell/breaker plate. As a result, it

: Sujit Kumar Dey, Shobhana Dey, Avimanyu Das

DESIGN, FABRICATION AND TESTING OF A

2023322 ABSTRACT: The laboratory size hammer mill was fabricated from locally available materials for crushing of minerals such as calcite, dolomite, limestone, granite

:MillFile Size:777KBPage Count:11

Hammer Mill CrusherGrinder 911 Metallurgist

2016225 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

Hammermill and roll crusher maintenance and

2023622 How to optimize performance and minimize maintenance costs in grinding processes.

What Is a Hammermill and What Can It Do for You? Eagle Crusher

2021110 In the aggregate crushing industry alone, the hammermill is able to crush a wide range of materials, including asphalt, concrete, brick, limestone, and coal, and

:Mining EngineeringEagle Crusher HammermillsHammermill Aprons

Study of the Energy-Power Parameters of the Crushing Process in Hammer

202336 Research goals: development of analytical method of determination of energy-power parameters of the drive of the hammer crusher with the grate;

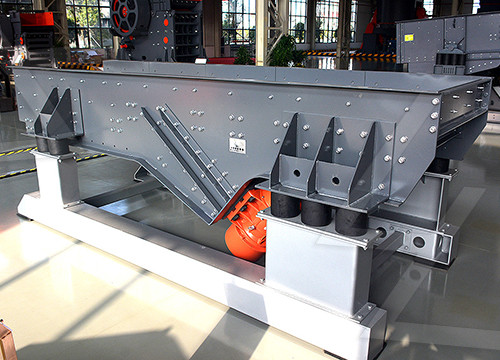

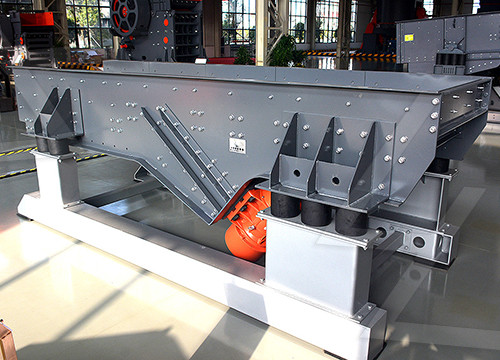

Hammer Crusher Machine Big Crushing Ratio And High

Our hammer mill grindershave a high degree of automation, automatic oil filling and intelligent online monitoring, which makes the machine maintenance more convenient and reduces the labor intensity of workers. Low consumption and energy saving. Our hammer crusher machine can save the energy more than 50% than the same type of products.

Hammer Mill crusher 3D CAD Model Library GrabCAD

201229 Abd Jalil Bin Abd Wahab. February 9th, 2012. this is hammer mill crusher, used in the palm oil industry to crush kernel. Download files. 889 Downloads 27 Likes 10 Comments.

Crusher an overview ScienceDirect Topics

A hammer crusher is suitable for mid-hard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc. 9.3.2.1 Coal Hammer Crusher Operating Principles. Hammer mills are primarily steel drums that contain a vertical or horizontal cross-shaped rotor mounted with pivoting hammers that can freely swing on either end of the cross.

Hammer Crusher Hammer Mill Machine AGICO Hammer Mill

A Hammer crusher (hammer mill machine) is a kind of equipment for crushing materials into smaller pieces by the repeated blows of little hammers. It is suitable for crushing the material with medium hardness and brittleness, the compressive strength is no more than 150 mpa and humidity is no more than 15%, widely used in cement plant, chemical

Study of Hammer Mill Crusher'': A Project Report ON Scribd

2021627 The project deals with the design of shaft and rotor assembly for hammer mill crusher of capacity 0.1(100 kg/hr.) tones per hour transmitting 20 B.H.P and speed of 750rpm. The design is based on the standard design procedure. In the present work by using the standard design procedure diameter of rotor shaft of hammer mill

International Journal of ChemTech Research

2019321 In this project the shaft and rotor assembly of hammer mill crusher was modelled using Pro-e modelling. Meshing of the shaft model was done and the loads, stresses that were applied for the shaft to be checked out that the design should be safe one. 2.Critical Parts Design 2.1 Design Criteria * Crusher Capacity = 100 Kg/h

Design, Fabrication and Performance Evaluation of a Stone Crusher

2021917 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h, through-put efficiency was found to be 75.4 %. The crushed products were well graded with 1.89 coefficient

Hammer Mill Principle, Construction, Working, and More

20231030 The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

What Are the Differences Between The 7 Types of Crushers?

2023215 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

Investigation of breakage characteristics of low rank coals in

201441 A hammer mill, an impact-type crusher, is one of the most extensively used mills for coal crushing, and it provides high-performance breakage. A major drawback of using the hammer mill, the wear and tear of hammers, appears negligible or less important especially for the crushing of LRC, which is generally softer than high-rank coal.

DESIGN, FABRICATION AND TESTING OF A

2023322 employing steel materials such as hammers mill has revolutionize the processing of minerals in a small scale and large scale capacity. There are various types of machines generally used for size reduction of materials. These are Gyratory crusher. Jaw crusher, Ball mill, Burr mill and many others. Thus, of all the crushing

Hammer mill, Hammer grinding mill All the

grain mill 6NF-4H 3IN1. limestone hammer stationary. Production capacity: 150 kg/h. 1.Top Grain Vibrator can clean the paddy 2.Double Layers’ Vibrator can separate the white limestone into whole A grade limestone and Half B Grade 3.

(PDF) Design and Performance Evaluation of a Stone Crusher

2021107 The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The

Design and Analysis of Rotor Shaft Assembly of Hammer

II. WORKING OF MACHINE When coal is delivered to the hammer mill crusher, it is prepared for cyclone furnace firing by being crushed into 1/4 inch or smaller size coal. Coal enters from the top and is violently thrown against the breaker blocks by the hammers. The final crushing is done between the hammer faces and the screen bars.

(PDF) Development of a Horizontal Shaft Hammer Mill

2020131 The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse materials of cassava tuber, yam tuber

Back to Basics Hammer Milling and Jet Milling

20171023 feeding (e.g., making metering into the mill difficult), grind-ing (e.g., plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (e.g., plugging the bag filters). There are two ways to grind sticky materials. The first solution is to dry the material prior to grinding, or dry and

Hammer Crusher_The Nile Co., Ltd.

202169 Hammer crusher (Hammer mill crusher) is suitable to use in gold ore mining project, especially small business.People can use hammer crusher to crush gold rock stone into small size, 0-5mm. Easy ways to get the answers you need. Service Online. Hammer crusher (hammer mill crusher) crushes through the collision between high-speed

Analysis of simulation result by digital filtering technique and

20171210 The model was validated using the independent experimental data of single coal tests with the laboratory scale hammer mill and full operation audit data of an industrial hammer mill. The outcome of the energy-based swing hammer mill model is the capability to simulate the mill configurations and operating conditions on product size

Your No.1 Hammer Mill Crusher Manufacturer and Supplier

Your Best Hammer Mill Crusher Manufacturer in China. 1. Advanced design technology, strong structure, and impact resistance. 2, feeding granularity, high yield, good grain shape. 3. Powerful crushing, coarse, medium, and fine crushing in one step. 4, Compared with the output of 30%, needle (powder) less than 20%, more energy saving.

Animal Feed Hammer Mill pellet-richi

2022127 CAPACITY: 3-25T/H. MAIN POWER: 30-160KW. MODEL: SFSP. WhatsApp: +86 138 3838 9622. Email: enquiry@pellet-richi. As the main feed equipment of the feed industry, the animal feed hammer mill is an important factor in the formation of feed quality, feed remuneration, and animal feed processing cost. Therefore,

Evaluation of Impact Hammer Mill for Limestone

Evaluation of Impact Hammer Mill for Limestone Crushing for Acidic Soil. Engineering Science. Vol. 6, No. 2, 2021, pp. 27-32. doi: 10.11648/j..12 Received: May

(PDF) DEVELOPMENT OF A HORIZONTAL SHAFT

20191223 The actual capacity was obtained to be 301 kg/h after the performance evaluation of the machine, and it has a 98 % material

Comminution features in an impact hammer mill

201321 However, a major bottleneck in the application of the hammer mill has been the wear and tear of the hammers, grates and the inner shell/breaker plate. As a result, it

DESIGN, FABRICATION AND TESTING OF A

2023322 ABSTRACT: The laboratory size hammer mill was fabricated from locally available materials for crushing of minerals such as calcite, dolomite, limestone, granite

Hammer Mill CrusherGrinder 911 Metallurgist

2016225 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

Hammermill and roll crusher maintenance and

2023622 How to optimize performance and minimize maintenance costs in grinding processes.

What Is a Hammermill and What Can It Do for You? Eagle Crusher

2021110 In the aggregate crushing industry alone, the hammermill is able to crush a wide range of materials, including asphalt, concrete, brick, limestone, and coal, and

Study of the Energy-Power Parameters of the Crushing Process in Hammer

202336 Research goals: development of analytical method of determination of energy-power parameters of the drive of the hammer crusher with the grate;

Hammer Crusher Machine Big Crushing Ratio And High

Our hammer mill grindershave a high degree of automation, automatic oil filling and intelligent online monitoring, which makes the machine maintenance more convenient and reduces the labor intensity of workers. Low consumption and energy saving. Our hammer crusher machine can save the energy more than 50% than the same type of products.

Hammer Mill crusher 3D CAD Model Library GrabCAD

201229 Abd Jalil Bin Abd Wahab. February 9th, 2012. this is hammer mill crusher, used in the palm oil industry to crush kernel. Download files. 889 Downloads 27 Likes 10 Comments.

Crusher an overview ScienceDirect Topics

A hammer crusher is suitable for mid-hard and light erosive materials such as coal, salt, chalk, gypsum, limestone, etc. 9.3.2.1 Coal Hammer Crusher Operating Principles. Hammer mills are primarily steel drums that contain a vertical or horizontal cross-shaped rotor mounted with pivoting hammers that can freely swing on either end of the cross.

Hammer Crusher Hammer Mill Machine AGICO Hammer Mill

A Hammer crusher (hammer mill machine) is a kind of equipment for crushing materials into smaller pieces by the repeated blows of little hammers. It is suitable for crushing the material with medium hardness and brittleness, the compressive strength is no more than 150 mpa and humidity is no more than 15%, widely used in cement plant, chemical

Study of Hammer Mill Crusher'': A Project Report ON Scribd

2021627 The project deals with the design of shaft and rotor assembly for hammer mill crusher of capacity 0.1(100 kg/hr.) tones per hour transmitting 20 B.H.P and speed of 750rpm. The design is based on the standard design procedure. In the present work by using the standard design procedure diameter of rotor shaft of hammer mill

International Journal of ChemTech Research

2019321 In this project the shaft and rotor assembly of hammer mill crusher was modelled using Pro-e modelling. Meshing of the shaft model was done and the loads, stresses that were applied for the shaft to be checked out that the design should be safe one. 2.Critical Parts Design 2.1 Design Criteria * Crusher Capacity = 100 Kg/h

Design, Fabrication and Performance Evaluation of a Stone Crusher

2021917 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h, through-put efficiency was found to be 75.4 %. The crushed products were well graded with 1.89 coefficient

Hammer Mill Principle, Construction, Working, and More

20231030 The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

What Are the Differences Between The 7 Types of Crushers?

2023215 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

Investigation of breakage characteristics of low rank coals in

201441 A hammer mill, an impact-type crusher, is one of the most extensively used mills for coal crushing, and it provides high-performance breakage. A major drawback of using the hammer mill, the wear and tear of hammers, appears negligible or less important especially for the crushing of LRC, which is generally softer than high-rank coal.

DESIGN, FABRICATION AND TESTING OF A

2023322 employing steel materials such as hammers mill has revolutionize the processing of minerals in a small scale and large scale capacity. There are various types of machines generally used for size reduction of materials. These are Gyratory crusher. Jaw crusher, Ball mill, Burr mill and many others. Thus, of all the crushing

Hammer mill, Hammer grinding mill All the

grain mill 6NF-4H 3IN1. limestone hammer stationary. Production capacity: 150 kg/h. 1.Top Grain Vibrator can clean the paddy 2.Double Layers’ Vibrator can separate the white limestone into whole A grade limestone and Half B Grade 3.

(PDF) Design and Performance Evaluation of a Stone Crusher

2021107 The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The

Design and Analysis of Rotor Shaft Assembly of Hammer

II. WORKING OF MACHINE When coal is delivered to the hammer mill crusher, it is prepared for cyclone furnace firing by being crushed into 1/4 inch or smaller size coal. Coal enters from the top and is violently thrown against the breaker blocks by the hammers. The final crushing is done between the hammer faces and the screen bars.

(PDF) Development of a Horizontal Shaft Hammer Mill

2020131 The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse materials of cassava tuber, yam tuber

Back to Basics Hammer Milling and Jet Milling

20171023 feeding (e.g., making metering into the mill difficult), grind-ing (e.g., plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (e.g., plugging the bag filters). There are two ways to grind sticky materials. The first solution is to dry the material prior to grinding, or dry and

Hammer Crusher_The Nile Co., Ltd.

202169 Hammer crusher (Hammer mill crusher) is suitable to use in gold ore mining project, especially small business.People can use hammer crusher to crush gold rock stone into small size, 0-5mm. Easy ways to get the answers you need. Service Online. Hammer crusher (hammer mill crusher) crushes through the collision between high-speed

Analysis of simulation result by digital filtering technique and

20171210 The model was validated using the independent experimental data of single coal tests with the laboratory scale hammer mill and full operation audit data of an industrial hammer mill. The outcome of the energy-based swing hammer mill model is the capability to simulate the mill configurations and operating conditions on product size

Your No.1 Hammer Mill Crusher Manufacturer and Supplier

Your Best Hammer Mill Crusher Manufacturer in China. 1. Advanced design technology, strong structure, and impact resistance. 2, feeding granularity, high yield, good grain shape. 3. Powerful crushing, coarse, medium, and fine crushing in one step. 4, Compared with the output of 30%, needle (powder) less than 20%, more energy saving.

Animal Feed Hammer Mill pellet-richi

2022127 CAPACITY: 3-25T/H. MAIN POWER: 30-160KW. MODEL: SFSP. WhatsApp: +86 138 3838 9622. Email: enquiry@pellet-richi. As the main feed equipment of the feed industry, the animal feed hammer mill is an important factor in the formation of feed quality, feed remuneration, and animal feed processing cost. Therefore,

دار آلة طحن

أطلقت الطوب فيديو

مصنع مسحوق الفحم جزء لكل تريليون

الذهب الخالص والحديد من الرمال

عالية الأداء محرك الديزل المتنقلة الشاشة تهتز للبيع

وظيفة كسارة الفك من الذهب

الفحم آلة الطارد NMB

الصين Pulvorizer Roler مطحنة

كسارة خام صخرية سماوية

تدفق البخار طاحونة متناهية الصغر

north island coromandel

قمائن الأسمنت الدوارة مستعملة للبيع

مدیر سنگ شکنمیکسر آسفالت

Sand production line manufacturer Stone production line

الحصى مطحنة الحجارة للبيع

مواصفات المسبار محطم

کارخانه انبار سرد و ماشین آلات soquimich

غسل الفحم مصنع أندونيسيا

آلة محرك صغير يعمل كوم

هيونداي معدات ثقيلة جدة

طاحونة الجذع للإيجار هيوستن تكساس

تطبيق أمبير أمبير الكسارات

مجلس الاسمنت الكسوة سنغافورة

التشغيل اليدوي سيمونز مخروط محطم

الكرة المستخدمة في الاسمنت

خام الحديد عملية النباتات benefication

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20