الحار منتجات

ملكنا الإخبارية

Flip Flow Screen Steam Coal Preparation Plant Process

Application of screening using a flip-flow screen and shallow

2023214 In this , the process of screening using a flip-flow screen and density separator using a shallow groove dense-medium separator for steam coal was proposed and applied to the Lijiahao coal preparation plant. Kinematics of the screen box and the

Application of flip flow screen in Sihe Coal Preparation

2017828 flow screen are elaborated,and the development process of flip flow screen in Chinese coal preparation industry are introduced.Flip flow screen,which is in the

Application of flip flow screen in Sihe Coal Preparation Plant

20161022 Flip flow screen, which is in the forefront of the domestic counterparts, has been comprehensive application in Sihe Coal Preparation Plant. The application

Application of screening using a flip-flow screen and shallow

20201221 In this , the process of screening using a flip-flow screen and density separator using a shallow groove dense-medium separator for steam coal was

Application of screening using a flip-flow screen and shallow

20201221 In this , the process of screening using a flip-flow screen and density separator using a shallow groove dense-medium separator for steam coal was

A novel and low cost coal separation process: Combination

202051 This negatively affects the separation processes and the normal operations of coal preparation plants [12, 13]. One type of equipment that can help to overcome the

Yuemin ZHAO PhD China University of Mining and

Introduction Skills and Expertise Fluidization Coal Energy Engineering Process Engineering Modeling and Simulation Energy Utilization Publications Publications (298) Study on

Study on screening probability model and particle-size effect of flip

202281 Flip-flow screening is an important method for classifying fine particles. As the lower limit of classification decreases during the screening process, the influence of

Research on Sieving Performance of Flip-Flow Screen Using

Research on Sieving Performance of Flip-Flow Screen Using Two-Way Particles-Screen Panels Coupling Strategy. Abstract: Sieving performance of flip-flow screen determines

International journal of coal preparation and utilization

Application of screening using a flip-flow screen and shallow groove dense-medium separation in a steam coal preparation plant Added 325 days ago (28.12.2020) Authors:

Variable elliptical vibrating screen: Particles kinematics and

2021111 1. Introduction. Coal is one of the most important fossil energy sources in the world [1], [2], [3].In 2019, coal consumption accounted for 57.7% of the total national energy consumption in China [4].Although coal has greatly contributed to the development of the world economy and industrial production, smoke and harmful gases formed due to

(PDF) Dynamical characteristics of flip-flow screen with

2022924 Flip-flow screen with crankshaft-link structure (FFSCLS) is effective for screening of high-water and fine materials. In this , a dynamic model governing the vibration and mechanical

Simultaneous multiple parameter optimization of variable-amplitude

2019315 One of the most widely used screening technologies for steam coal preparation after removal of fine fractions, is a 6 mm screening method. We propose a novel variable-amplitude equal-thickness elastic screen (VAETES) to solve the problem of material accumulation and screen aperture blockage during the 6 mm screening process of steam

A novel and low cost coal separation process: Combination

202051 This negatively affects the separation processes and the normal operations of coal preparation plants [12,13]. One type of equipment that can help to overcome the problem of coal slime is the flip-flow screen. These screens have the advantage of being able to sieve high viscosity, high moisture and fine-grained materials effectively [14

Research on highly efficient quality improvement process

1. Introduction. Steam coal is an important coal resource and that is used as a fuel in electric power plants to generate steam for producing electricity, it accounts for large proportion in the coal structure [[1], [2], [3]].Coal preparation is a key link to achieve effective improvement in the quality of steam coal for its clean utilization [[4], [5], [6]].

Kinematics characteristics of the flip-flow screen with a

2021121 The flip-flow screen with a crankshaft-link structure (FFSCLS) is a key technology for the separation of fine wet coal which can greatly improve the economic benefits of the coal preparation plant. The classification effect of the FFSCLS was studied, and the results showed that with an increase in the tension of the screen surface and

Bo ZHANG Dr Doctor of Engineering ResearchGate

Application of screening using a flip-flow screen and shallow groove dense-medium separation in a steam coal preparation plant. link type flip-flow screen in the screening process, a vibration

Haishen Jiang's research works China University of Mining

In this , the process of screening using a flip-flow screen and density separator using a shallow groove dense-medium separator for steam coal was proposed and applied to the Lijiahao co

Application of screening using a flip-flow screen and shallow

20201221 Request PDF Application of screening using a flip-flow screen and shallow groove dense-medium separation in a steam coal preparation plant Low-rank steam coal is an important coal resource

Kinematics of a novel screen surface and parameter optimization for

2020315 Some steam coal preparation plants have separated the −13(25) mm raw coal by a dense medium cyclone, affording a large amount of coal slime and considerably reducing the calorific value of the part of the fine coal. an elastic cantilevered vibrating screen, a flip-flow screen, and others, realizing highly efficient screening [32,33

Vibration Characteristics of an Industrial-Scale Flip

2021927 The flip-flow screen with crank-link structure (FFSCLS) is an essential technology for separation of fine moist coal which can significantly improve the economic benefits of the coal preparation plant .

Application of flip flow screen in Sihe Coal Preparation Plant

20161022 The application practice and effect of flip flow screen on raw coal screening, desliming before lump and slack coal separation, dehydration and sculping of slack coal are comprehensively introduced. The undersize fraction and the oversize fraction are simultaneously decreased because of the application of flip flow screen on raw coal

Kinematics of a novel screen surface and parameter optimization for

2020315 The −3 mm classification technology for the large-scale upgrading and processing of steam coal is being followed, thereby promoting the flexible adjustment of the process flow in steam coal preparation plants and optimizing the product structure. Raw coal of less than 3 mm is directly supplied to power plants.

A novel and effective method for coal slime reduction of thermal coal

20181010 In this , a dynamic process, consisting of coal processing slime reduction, is put forward in view of the easy-to-agglomerate long flame coal, −3/-6 mm screening and wide grain shallow tank heavy-medium separation. The coal sieving −3/-6 mm flip flow screen and shallow tank heavy-medium separation system can realize 100-3 mm

ORCID

202396 Application of screening using a flip-flow screen and shallow groove dense-medium separation in a steam coal preparation plant. International Journal of Coal Preparation and Utilization the Collision Mechanics Model and Time-Frequency Characteristics during the Multistage Variable-Inclination Screening Process for Clean

What Is Coal Preparation? Energy.gov

2013221 What Is Coal Preparation? • Coal preparation is the removal of undesirable material from the Run-of-Mine (ROM) coal by employing separation processes which are able to differentiate between the physical and surface properties of the coal and the impurities. Through coal preparation, a uniform product is achieved.

Kinematics of elastic screen surface and elimination

2019315 Coal preparation is the most economical way to reduce air pollution and can boost clean and sustainable use of coal [[4], [5], [6]]. With the increase in separation efficiency and the use of steam coal, the deep screening technology, which can simplify the cleaning process, has become the technology of choice for steam coal preparation plants

Application of screening using a flip-flow screen and shallow

20201221 Application of screening using a flip-flow screen and shallow groove dense-medium separation in a steam coal preparation plant International Journal of Coal Preparation and Utilization ( IF 2.697) Pub Date : 2020-12-21, DOI: 10.1080/.2020.

Dynamic characteristics of LIWELL flip-flow screen panel and

20211214 Flip-flow screens are widely used and developed as they have several advantages such as high acceleration, high screening efficiency, strong adaptability, and small overall dynamic load (Dong et al., 2013, Zhang, et al., 2018, Peng et al., 2019). These advantages of flip-flow screens result from the fact that the flexible screen panel can

A review on the advanced design techniques and methods

201941 After the raw coals are treated by the separator, vibrating screen, crusher, centrifuge, the particle size decreases from more than 100 mm to the final 2–25 mm, and meanwhile, the ash content decreases from 27.8% of the raw coal to 8.1% of the final clean coal. During this coal preparation process, the vibrating screens used include a flip

بناء كسارة مخروطية الحجر المنجم الهيدروليكية

كسارات الجرانيت في العراق

اكتشاف التعلم الكلية مختبر الهندسة

مطحنة 45 بوصة 2 أ

المكثف الطرد المركزي

كسارة الفك بيع الصين المستعملة

مطحنة الكرة الصغيرة ذات السرعة المتوسطة من سلسلة Hgm المعتمدة من Iso

كسارة مسن دامباك

كسارة الحجر kesempatan

máquina de molienda millies

كسارة الحجر المتنقلة الجبس

سنگ شکن موبایل در کانادا ساخته شده است

تهتز الشاشة لمسحوق الزجاج

الأكثر مبيعا كسارة تصادمية طحن الدولوميت

الأهداف العامة لمعدات التكسير

حجر النهر محطم كوريا السلبي مع السعر

تجديد معدات الطحن للحد من قطر

تولید کنندگان تسمه های لاستیکی

الالات طحن صغيرة في موقع المزون

الاهتزاز المغذية gzd

تجار الزجاج المطاحن في الولايات المتحدة الأمريكية

استخراج الحديد السطح

crushing equipment for magnetite

مطحنة الكرة وطاحونة الكرة وعاء السلطانية

البازلت صخور مطحنة

كيفية استخراج الذهب من التليفون المحمول

حول لدينا

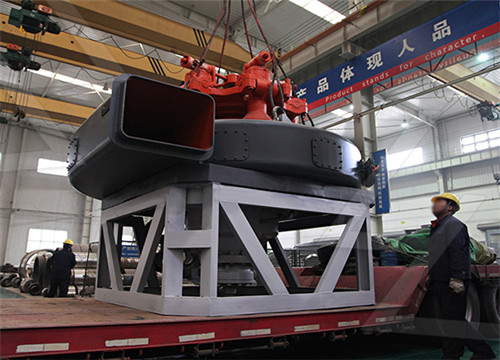

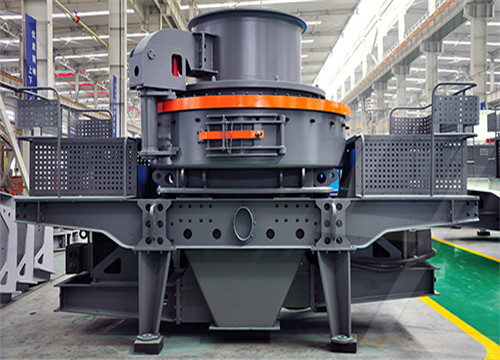

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20