الحار منتجات

ملكنا الإخبارية

copper ore crushing

Current Status of Copper-Ore Processing: A Review Springer

202198 The ore processing flowsheet includes crushing, grinding to a size of 80% passing –180 μm, the first bulk flotation with regrinding of the flotation tailings to a size of

A novel crushing pretreatment:Inhibitory effect for

202011 In this , a novel crushing pretreatment: the inhibitory effect for micro-fine particles of China copper ore was investigated based on high voltage pulse. The ore

Crushed ore agglomeration and its control for heap leach

201321 HPGR comminuted copper ore (andesite rock matrix high in silica, more than 1% copper and high acid consuming species) followed by agglomeration and small

Preferential sequence crushing of copper ore based upon

2019115 The particle size, shape coefficient and preferential crushing index ( Δ α i) were determined using systematic experiments. The parameters were further

Copper Ore an overview ScienceDirect Topics

Overview Mark E. Schlesinger, Gerardo R.F. Alvear Flores, in Extractive Metallurgy of Copper (Sixth Edition), 2022 1.3.1 Concentration by froth flotation Copper ores being

Preferential sequence crushing of copper ore based upon

2019115 Abstract In this study, high voltage pulse breakage was used to study the breakage process of copper ore. The particle size, shape coefficient and preferential

Transparency on greenhouse gas emissions from mining to enable Nature

202023 For copper mining, fuel consumption increased by 130% and electricity consumption increased by 32% per unit of mined copper in Chile from 2001 to 2017,

Particle damage and exposure analysis in HPGR crushing of

2011101 Copper ores (copper oxide ore and copper sulfide ore) were crushed by a jaw crusher and by HPGR. Crushed and sized products were evaluated for particle

Kinetic Investigation on Leaching of Copper from a Low-Grade Copper

2021728 In the second stage, the leaching kinetics was studied by shrinking core models to gain a better description of the dissolution process of copper from crushing

Minerals Free Full-Text The Delineation of Copper

20231031 Six copper geochemical blocks, each with an area of more than 1000 km 2, were all spatially consistent with the locations of the five Cu ore districts (Edongnan,

Transparency on greenhouse gas emissions from mining to enable Nature

202023 However, in copper mining, crushing and grinding are the most energy-intensive parts of the production chain and are the main contributors to its GHG emissions 4. Life-cycle assessment.

ore(): Cambridge Dictionary

ore:(),。。 Different panels would reflect the various stages of mechanical production and assembly, from mineral ore in the soil to finished product, driving into the sunset.

A novel crushing pretreatment:Inhibitory effect for

202011 Copper ore was collected from Fu Shun, Liao Ning province, China. This study magnetization roasts hematite ore after mechanical crushing and HVPD, analyzing the difference in the roasting effect between the two crushing methods by establishing a new system of HVPD-magnetization roasting. For a roasting temperature of 500 °C, roasting

Chemical Composition Data of the Main Stages of Copper

2022216 The mining industry has faced significant challenges to maintaining copper production technically, economically, and environmentally viable. Some of the major limitations that must be overcome in the coming years are the copper ore grade decline due to its intense exploitation, the increasing requirements for environmental protection, and

Kinetic Investigation on Leaching of Copper from a Low-Grade Copper

2021728 According to Table 1, the ore sample indicated about 3.91% copper (4.90% CuO) in the original feed from mine, while it was included about 0.33% copper (0.41% CuO) for the reject sample studied.Furthermore, to investigate the effect of particle size on copper dissolution, dry sieving was practiced in laboratory and two particle size

Preferential sequence crushing of copper ore based upon

2019115 The crushing of the ore can be represented by For this copper ore, the main components are quartz and anorthose, and the dielectric constant are 4.2–5.9 and 5.1–5.7, respectively. It is far less than that of chalcopyrite and pyrite, which is 81 and 33.7–81 respectively. In the breakage process for chalcopyrite and pyrite from this

Copper processing Ores, Refining, Smelting Britannica

Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores. Native copper is simply the metal found unadulterated in nature. Occasionally copper is still found in its native form, but more frequently it is mixed with other minerals, some of which may have value themselves. The amount of copper in

Copper Processing Multotec

Following mining, transporting, and crushing to the required size, the crushed ore is further processed through a mill and then secondary milling and classification. Yet, the most common source of copper ore is the sulphide ore mineral chalcopyrite, which accounts for around 50% of copper production in the world. Types of Copper Ore

Crushed ore agglomeration and its control for heap leach

201321 HPGR comminution within a crushing circuit, in specific instances, can result in more than 2–10% increase in copper extraction (Baum and Ausburn, 2011). HPGR comminuted copper ore (andesite rock matrix high in silica, more than 1% copper and high acid consuming species) Quality control (QC) and characterization tools

Heap Leaching an overview ScienceDirect Topics

The copper heap leaching, solvent extraction, and electrowinning process has revolutionized the copper industry and significantly reduced the capital and operating costs for the production of copper from low-grade ores.A schematic of a typical heap leach/SX/EW operation is shown in Fig. 4.29.The SX part of the flowsheet recovers about 80%–90% of

stone crusher used as copper ore crusher-CSDN

2016127 In addition, cone crusher which is called stone of copper crusher also can be used as secondary crusher. As professional copper Used Copper Crushing Plant - Rock Crusher Copper Crusher >> Copper Ore Crusher Like a major mining crushing equipment manufacturer in China, our impact crusher is traditionally used as

Copper Sulfide Flotation 911 Metallurgist

2016413 The Porphyry Copper Extraction Process Flowsheet Crushing Porphyry Copper Ores. Three stage crushing is illustrated in the flowsheet; however, it is possible and practical to eliminate the third

(PDF) Agglomeration and leaching behaviors of copper

202171 Abstract. The chemical binder is one of the critical factors affecting ore agglomeration behavior and leaching efficiency. In this study, we investigated the effect of the type of binder and mass

Copper Mining and Processing: Processing Copper Ores

2 This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis. Following mining, transporting, and crushing to a consistent gravel or golf ball-size, the crushed ore is further processed at a mill

Agglomeration and leaching behaviors of copper oxides with

2021718 The chemical binder is one of the critical factors affecting ore agglomeration behavior and leaching efficiency. In this study, we investigated the effect of the type of binder and mass fraction of the H2SO4 solution used on the curing, soaking, and leaching behavior of agglomerations. The results revealed that Portland cement

Copper Ore Crushing, GrindingFlotation 911 Metallurgist

2017521 Grinding and Flotation. Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8’-6 x 13’-0) Hardinge rod mill at an average feed rate of 2,106 STPD or 87.75 STRH. Rod mill discharge at a nominal size of minus 16 mesh and a pulp density of 75 percent solids combines with ball mill discharge

What is the process of crushing copper ore? LinkedIn

Published Mar 16, 2023. + Follow. The process of crushing copper ore is a multi-stage process that involves breaking down the ore into smaller pieces and gradually reducing the size of the

Copper Ore Processing Plants, Flow And Equipment

20231020 Preparation process before separation. Including copper ore crushing, screening, grinding, grading and other processes. The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other 1. Crushing process The copper ore that needs to be processed must

Copper Ore Beneficiation Processing Technology JXSC

20221230 The processing technology of copper ore beneficiation plants includes flotation, microbial leaching, segregation, beneficiation, etc. Single sulfide ore is mostly processed by flotation, and copper ore processing equipment adopts the crushing-grinding-classification-flotation-concentration process to select single copper sulfide ore as copper

SUSTAINABILITY OF COPPER SLAG PROCESSING FROM NEW

The copper ore treatment process in RTB Bor produces significant amounts of mine waste material such as: mining waste, flotation tailing and copper slag (Stanojlovic et al., 2014). The Copper Mine Bor started production in 2001, treating copper slag by flotation, after crushing and grinding (Stanojlovic et al., 2014). Slag processing

كاولين كسارة محمولة للبيع في ماليزيا

سنگ زنی با مته سوراخ کردن اطلاعات دستگاه

كسارة في ريو غراندي بيع

خام النيكل للبيع في غرب المملكة العربية السعودية

مشروع تعدين الفحم cese بالقرب من أسانسول

فريق مطحنة رطب فرنسا

سعر كسارة صغيرة في السعودية

كسارة خام الحديد الكروم اختيار مسحوق الحديد الكروم

الموقد لصناعة الأسمنت المصنعين

معدات سحق السيارات

crushing ore copper ore

ريمون تعمل الطحن

مقاطع ديد تسن محجره

معدات مطحنة الكرة المتنقلة عمان

تكلفة بناء الطحن

طحن جديد من طاحونة الاسمنت قدرة تصل إلى طن في الساعة

عملية سحق الحجر الجيري في vsk

صور جهاز ال roller mill

جودة شراء حجر آلة محطم من الشركات المصنعة تعدين الذهب

الاصطناعي صنع الرمال سعر الجهاز

ماكنه طحن الكرتز

بيع كسارة الرمل متناهية الصغر

ماكينات تصنيع الشموع

مصادر المعدات الثقيلة

برنامه برای دستگاه های سنگ شکن شن

جزء لكل تريليون في صنع عملية ملموسة

حول لدينا

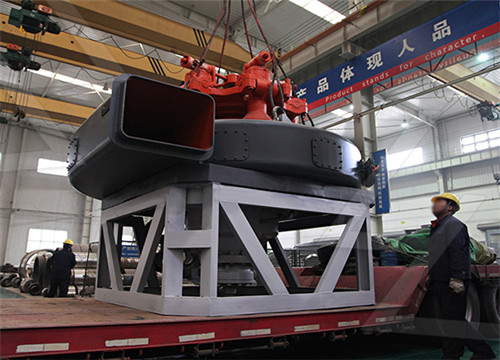

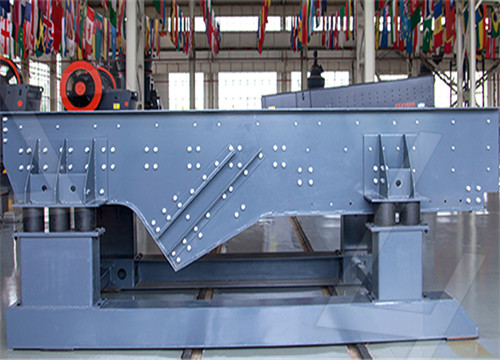

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20