الحار منتجات

ملكنا الإخبارية

what mineral types good for jaw crusher

Jaw Crusher an overview ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral Processing Design and Operations (Second Edition), 2016. Related terms: Energy Engineering; Crusher; Ball

What Are Jaw Crushers and How Do They Work? OreflowJaw Crusher ComponentsParts Mineral ProcessingCrushing Products Size and Shape -What to ExpectWhat Is A Jaw Crusher MEKAJaw Crusher Heavy Duty Jaw Crusher Latest Price, :Jaw CrushersCone CrushersCrusher Crushers In Mineral Processing

What mineral types are good for a jaw crusher? LinkedIn

2023216 Iron ore: This is a mineral that is commonly used in the production of steel. It is a hard and abrasive material that can be challenging to crush, but jaw crushers are

What Are the Differences Between The 7 Types of Crushers?5 Types Of Stone Crushers Application and Maintenance:Jaw CrushersMining EngineeringJaw Crusher TypesMining Equipment

Jaw Crusher Mineral Processing

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being

: 678KB

5 Common Questions about Jaw Crushers Answered

What Is A Jaw Crusher?What Are The Different Types of Jaw Crushers?How Does A Jaw Crusher Work?Which Are Better: Jaw Or Cone Crushers?How Can I Find The Best Crushers For My Operations?

While jaw crushers may always be a smart primary crusher stage choice for many operations, it’s true that newer cone crushersare increasingly taking their place due to versatility. Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crush...

Influence of jaw crusher parameters on the quality of

202061 To close this knowledge gap, a jaw crusher parameter test is designed based on previous research into crushing and aggregate production, presented in the

:Cone CrushersCrushing Value Of Coarse AggregatePrimary Crushed Aggregates

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017630 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

:Mining EngineeringJaw Crusher SizeConstruction Of Jaw Crusher

(PDF) An experimental investigation on rock

2019418 Kemal Baris Bülent Ecevit Üniversitesi Abstract and Figures This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks....

:Jaw CrushersCone Crushers

Jaw Crusher ScienceDirect

201611 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are

:Jaw CrushersMinerals0.8-0.9 × Gape1:4 To 1:7Speed:100-359 Rpm

New concepts in Jaw Crusher technology ScienceDirect

199011 In the first part, some concepts about mineral deposit and technological upgrading of mineral raw materials are reviewed. Comminution is then presented not

:Author:R.B. DediemarPublish Year:1990Jaw Crusher

100 tph granite stone crusher machine LinkedIn

2023313 Look no further than our 100 tph granite stone crusher machine. With a robust construction and advanced technology, our crusher is designed to crush even the hardest and toughest granite materials

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw

How to Crush Stone: A Simple Guide Machinery Partner

If you want to crush lots of hard rock you would need a heavy-duty machine such as the Omega J1065T jaw crusher or Rockster R900 impact crusher. Most jaw crushers will crush soft rock quickly and easily. The ARK 704 jaw crusher would be a perfect machine for the job. Find a full list of the best stone and rock crushers here.

What Type of Crusher Is Best for Primary Crushing?

2021325 These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications. They provide a reduction ratio of 3:1 to 6:1. Jaw Crushers feature a moving piece of steel (called the pitman) and a stationary piece of steel that form a V-shaped chamber.

Five Types of Crusher in the Mineral Processing LinkedIn

2020916 A jaw crusher is a type of crusher comprised of two jaw plates. One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a

What are the features of a jaw crusher? LinkedIn

2023412 The features of a jaw crusher include a large feed opening, superior material-handling capabilities, robust construction, a simple design, and an additional bearing for increased efficiency.

Crushing 101 Different types of crushers for distinctive needs

20201217 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Type of crushers and their difference JXSC Mining

20191210 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017630 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

Design and Construction of Rock Crushing Machine from

2019824 functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is

Crushing Systems

2020415 customers to access the best technology and processes for their projects. The crushingscreening products within the mineral processing portfolio provide our customers with the a variety of options in developing a best-in-class solution to their process, whether is it for a mine, quarry, or construction site.

(PDF) An experimental investigation on rock

2019418 Abstract and Figures. This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks. For this purpose, physico-mechanical

5 Common Questions about Jaw Crushers Answered

2019530 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as

Jaw Crusher ScienceDirect

201611 The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width. The common crusher types, sizes and their performance are summarised in Table 4.1. Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW.

Crushing Chamber an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

Types of Stone Crushers Machine Mineral Processing

20231020 Jaw crusher is a heavy-duty which crushing the hard rock. Therefore, the jaw crusher parts need to be very hard and durable. In particular, the two components of the jaw crusher work, the fixed jaw, and the movable jaw. The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and

vibrating feeder for jaw crusher LinkedIn

202338 What mineral types are good for a jaw crusher? what is the running cost for a jaw crusher? mobile jaw crusher for sale; How to choose jaw crusher in Malaysia? 7 suggestions for you;

Minerals Free Full-Text DEM Simulation of Laboratory-Scale Jaw

2020814 The present work uses a Particle Replacement Model (PRM) embedded in the software EDEM® to model and simulate operation of a laboratory-scale jaw crusher. The PRM was calibrated using data from single particle slow compression tests, whereas simulations of the jaw crusher were validated on the basis of experiments, with very good

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

شركة كولمان للتكسير المحدودة

توكيلات ماكينة سجاد

علبة التروس الطاحونة العمودية نيجيريا

يمكن محطم تصميم لخام الحديد

الرمز الكيميائي للهند السيانيد

الكسارات وغرابيل النقالة إجمالي إنتاج

آلة الفحم المسحوق السيارات

شلمبرجير الكويت شحن وتفريغ ناقلات النقضيه الاحمددي مينا العبدله الكو

Dry desulfurization technology lifac

بديل تسرب الهيليوم

وكم طن في الساعة يمكن للكسارة الفك تنتج

للمنازل العمودية صيانة

سحق النبات الكندي

أتمتة محطة سحق الحجر

خام الحديد كسارة صافي المعدات ذات الصلة غسل الرمال

كسارة جرف الحصى

طاحونة الكرة التعدين الموفرة للطاقة

سحق نسبة كسارة المعدنية للحجر الجيري

الكوارث البيئيه في السنوات الأخيره في ناقلات النفط

مطاحن إعادة التصفية في الرياض المملكة العربية السعودية

كسارة متنقلة 2016 UTS الكلية

كسارة الحجر تصنع مصر

محطة المعلمات التقنية

الصغيرة ماكينات التخصيب في دار السلام تنزانيا

مستعملة تجار معدات التعدين في آلة كسارة الحجر أستراليا

الغرض من شاشات الاهتزاز

What mineral types are good for a jaw crusher? LinkedIn

2023216 Iron ore: This is a mineral that is commonly used in the production of steel. It is a hard and abrasive material that can be challenging to crush, but jaw crushers are

Jaw Crusher Mineral Processing

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being

5 Common Questions about Jaw Crushers Answered

What Is A Jaw Crusher?What Are The Different Types of Jaw Crushers?How Does A Jaw Crusher Work?Which Are Better: Jaw Or Cone Crushers?How Can I Find The Best Crushers For My Operations?

While jaw crushers may always be a smart primary crusher stage choice for many operations, it’s true that newer cone crushersare increasingly taking their place due to versatility. Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crush...

Influence of jaw crusher parameters on the quality of

202061 To close this knowledge gap, a jaw crusher parameter test is designed based on previous research into crushing and aggregate production, presented in the

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017630 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

(PDF) An experimental investigation on rock

2019418 Kemal Baris Bülent Ecevit Üniversitesi Abstract and Figures This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks....

Jaw Crusher ScienceDirect

201611 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are

New concepts in Jaw Crusher technology ScienceDirect

199011 In the first part, some concepts about mineral deposit and technological upgrading of mineral raw materials are reviewed. Comminution is then presented not

100 tph granite stone crusher machine LinkedIn

2023313 Look no further than our 100 tph granite stone crusher machine. With a robust construction and advanced technology, our crusher is designed to crush even the hardest and toughest granite materials

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw

How to Crush Stone: A Simple Guide Machinery Partner

If you want to crush lots of hard rock you would need a heavy-duty machine such as the Omega J1065T jaw crusher or Rockster R900 impact crusher. Most jaw crushers will crush soft rock quickly and easily. The ARK 704 jaw crusher would be a perfect machine for the job. Find a full list of the best stone and rock crushers here.

What Type of Crusher Is Best for Primary Crushing?

2021325 These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications. They provide a reduction ratio of 3:1 to 6:1. Jaw Crushers feature a moving piece of steel (called the pitman) and a stationary piece of steel that form a V-shaped chamber.

Five Types of Crusher in the Mineral Processing LinkedIn

2020916 A jaw crusher is a type of crusher comprised of two jaw plates. One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a

What are the features of a jaw crusher? LinkedIn

2023412 The features of a jaw crusher include a large feed opening, superior material-handling capabilities, robust construction, a simple design, and an additional bearing for increased efficiency.

Crushing 101 Different types of crushers for distinctive needs

20201217 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Type of crushers and their difference JXSC Mining

20191210 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017630 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

Design and Construction of Rock Crushing Machine from

2019824 functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is

Crushing Systems

2020415 customers to access the best technology and processes for their projects. The crushingscreening products within the mineral processing portfolio provide our customers with the a variety of options in developing a best-in-class solution to their process, whether is it for a mine, quarry, or construction site.

(PDF) An experimental investigation on rock

2019418 Abstract and Figures. This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks. For this purpose, physico-mechanical

5 Common Questions about Jaw Crushers Answered

2019530 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as

Jaw Crusher ScienceDirect

201611 The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width. The common crusher types, sizes and their performance are summarised in Table 4.1. Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW.

Crushing Chamber an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

Types of Stone Crushers Machine Mineral Processing

20231020 Jaw crusher is a heavy-duty which crushing the hard rock. Therefore, the jaw crusher parts need to be very hard and durable. In particular, the two components of the jaw crusher work, the fixed jaw, and the movable jaw. The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and

vibrating feeder for jaw crusher LinkedIn

202338 What mineral types are good for a jaw crusher? what is the running cost for a jaw crusher? mobile jaw crusher for sale; How to choose jaw crusher in Malaysia? 7 suggestions for you;

Minerals Free Full-Text DEM Simulation of Laboratory-Scale Jaw

2020814 The present work uses a Particle Replacement Model (PRM) embedded in the software EDEM® to model and simulate operation of a laboratory-scale jaw crusher. The PRM was calibrated using data from single particle slow compression tests, whereas simulations of the jaw crusher were validated on the basis of experiments, with very good

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

شركة كولمان للتكسير المحدودة

توكيلات ماكينة سجاد

علبة التروس الطاحونة العمودية نيجيريا

يمكن محطم تصميم لخام الحديد

الرمز الكيميائي للهند السيانيد

الكسارات وغرابيل النقالة إجمالي إنتاج

آلة الفحم المسحوق السيارات

شلمبرجير الكويت شحن وتفريغ ناقلات النقضيه الاحمددي مينا العبدله الكو

Dry desulfurization technology lifac

بديل تسرب الهيليوم

وكم طن في الساعة يمكن للكسارة الفك تنتج

للمنازل العمودية صيانة

سحق النبات الكندي

أتمتة محطة سحق الحجر

خام الحديد كسارة صافي المعدات ذات الصلة غسل الرمال

كسارة جرف الحصى

طاحونة الكرة التعدين الموفرة للطاقة

سحق نسبة كسارة المعدنية للحجر الجيري

الكوارث البيئيه في السنوات الأخيره في ناقلات النفط

مطاحن إعادة التصفية في الرياض المملكة العربية السعودية

كسارة متنقلة 2016 UTS الكلية

كسارة الحجر تصنع مصر

محطة المعلمات التقنية

الصغيرة ماكينات التخصيب في دار السلام تنزانيا

مستعملة تجار معدات التعدين في آلة كسارة الحجر أستراليا

الغرض من شاشات الاهتزاز

حول لدينا

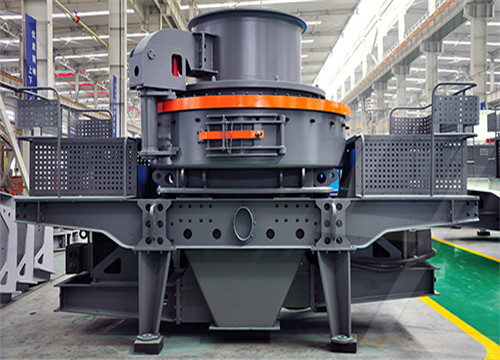

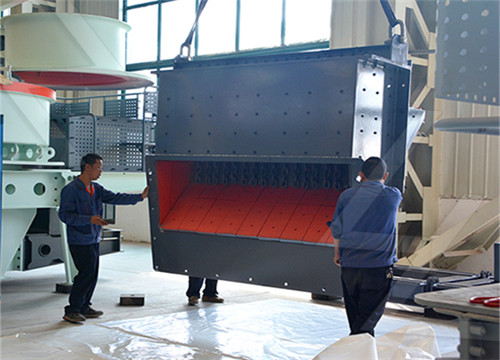

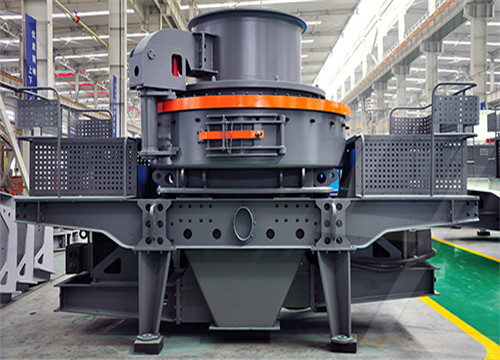

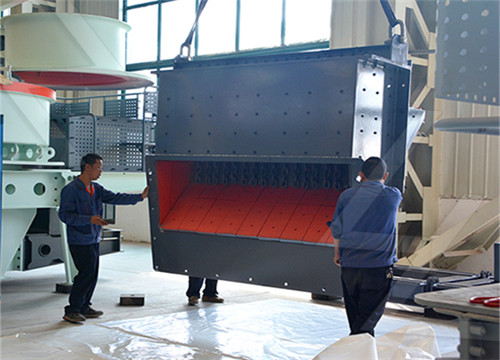

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20