الحار منتجات

ملكنا الإخبارية

primary amp secondary crushers used in conveyor belt

sbmchina/sbm primary secondary crushers used in conveyor belt

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

sbm primary 26amp 3 secondary crushers used in conveyor belt

Sign in / Register Toggle navigation Menu. M mill ; Project information Project information Activity

en/primary amp secondary crushers used in conveyor belt

. Contribute to sbmboy/en development by creating an account on GitHub.

Comminution and classification technologies of iron ore

202211 The geology is Brockman bedded iron deposit. Two stage crushing is used, jaw crusher for the primary and cone crushers for the secondary crushing. There are

Primary Crusher an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the

Downstream Crushing Options for Secondary,

2021412 For fine sizing, tertiary or even quaternary crushing stages may follow the primary and secondary stages. Cone Crushers are the most common types of tertiary and quaternary crushers, though Vertical Shaft

primary amp secondary crushers digunakan dalam belt conveyor

Contribute to luoruoping/id development by creating an account on GitHub.

Gyratory and Cone Crusher ScienceDirect

201611 Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large run-of-mine ore pieces to

Crushing Chamber an overview ScienceDirect Topics

Primary coal crusher: These crushers are used for bigger coal sizes and have different types such as the coal jaw crusher, the coal hammer crusher, and the ring granulator. (b)

Understanding the Different Types of Crushers Agg-Net

2018910 Jaw crushers are mainly used in primary crushing stages and are rarely used for secondary crushing. As a compression crusher, this type of machine generally

Primary and Secondary Crushing: Understanding

2023228 The primary objective of crushing is to reduce the size of the materials for further processing. Crushing is an energy-intensive process that involves different types of equipment, such as crushers, screens,

Developments in iron ore comminution and classification

201511 Primary/secondary: 1300: 200–300: Up to 1800: Cone crusher: Secondary 450 60–80Up to 1200: Cone crusher: Tertiary 150 < 30Up to 1000: Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw and a

sbmchina/sbm primary secondary crushers used in conveyor belt

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Selecting the right type of crushing equipment Quarry

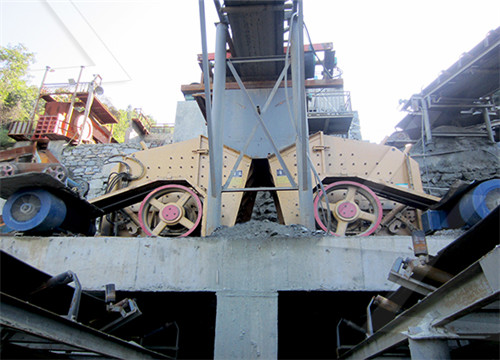

201647 Primary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt. In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used. As with primary HSI crushers, these secondary impactors, which open like a

Crusher an overview ScienceDirect Topics

Roll Crushers. A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 6.1.3 Roll Crusher Circuit Design. Roll crushers are generally not used as primary crushers for hard ores. Even for softer ores, like chalcocite and chalcopyrite they have been used as secondary crushers. Choke feeding is not advisable as it tends to produce particles of

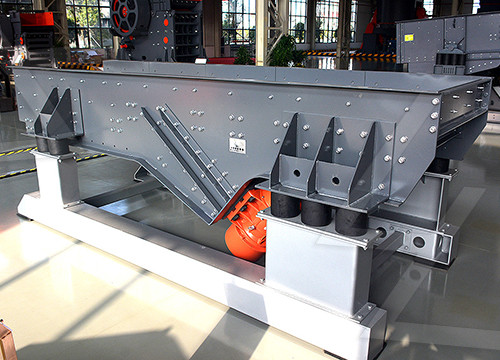

Belt Feeders MEKA

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you would like to be contacted by our sales team. CALL BACK INQUIRE NOW. MEKA Belt Feeders are

AMIT 135: Lesson 5 Crushing Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m. Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate:

Secondary Crushing Equipment 911 Metallurgist

2016228 The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation. This is tantamount to making the over-all reduction in one machine, except of course that there will always be a certain amount of surge capacity between the two crushers.

How Do Conveyor Belts Work? Belt Functions, Uses

1 A conveyor belt works by using two motorized pulleys that loop over a long stretch of thick, durable material. When motors in the pulleys operate at the same speed and spin in the same direction, the belt moves between the two. If objects are particularly heavy or bulky — or if the conveyor belt is carrying them for a long distance or

Primary Crusher SelectionDesign 911 Metallurgist

20151223 Primary Jaw Crushers. How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone

Types of Crushers: What You Need to Know Machinery

The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A. Edison’s research and development, giant machines were innovated and placed around the United States. Smaller-sized jaw crushers were also developed as secondary and tertiary crushers.

What Is Primary, Secondary, and Tertiary Crushing?

2021110 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Crushing Equipment Superior Industries U.S. Manufacturer

1 2-Year / 6,000 Hour. Superior crushers come backed by a rock-solid 2-year / 6,000-hour warranty against manufacturer defects. Superior manufactures fifteen American-made models, which are gaining a strong reputation. Connect with one of our crushing experts and find the right machine.

Tramp Metal Detection Advancing Mining Thermo Fisher

2022927 Tramp metal detection is the only reliable and cost-effective method of protecting expensive crushers, shredders, conveyor belts and in-line weighing, sampling and monitoring equipment. By detecting the presence of metal objects that conventional magnets may miss, tramp metal detection provides reliable protection to your processing equipment.

primary amp secondary crushers used in conveyor belt

كسارة تصادمية سلسلة PFW قاعدة على خبرة وفيرة من إنتاج وتسويق من كسارة تصادمية ، GM RD مؤسسة تصميم كسارة تصادمية سلسلة PFW.

P&Q University Lesson 7: CrushingSecondary Breaking

201992 HSI crushers can be primary or secondary crushers. In the primary stage, HSIs are better suited for softer rock, such as limestone, and less abrasive stone. In the secondary stage, the HSI can process more abrasive and harder stone. If present beneath the crusher, this deflector plate can keep tramp metal from degrading the

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as primary

Dunlop UsFlex® Dunlop Conveyor Belting

Dunlop UsFlex is available from stock in two tensile strengths; 630/1 6+3 and 1000/2 8+3 in widths up to 2000mm. UsFlex belts are supplied with the abrasion resistant ‘RS’ cover as standard. The Dunlop RS cover grade exceeds the very highest DIN and ISO grades (DIN W and ISO 14890 ‘D ‘). Other tensile strengths and cover qualities can

ازالة الحجاب في الحلم ابن سيرين

1800 شاشة فحص المواصفات

مصانع تعدين الذهب صغيرة الحجم للبيع

مختبر الفك محطم مصنعين في الهند

الفحم مطحنة دقة العينات

تستخدم الحجر الجيري الفك محطم سعر أنغولا

آلة تعدين مطحنة الكرة الرطبة تعدين الذهب

مُصنِّع كسارات فكية للبيع

أعمال التعدين نيجيريا

الكاولين المخروط كسارة المورد في اليمن

مطحنة البنتونيت مطحنة طحن البنتونيت طحن البنتونيت

يمكن الأسمنت سحق المعدات محطم

سكين المشقق آلة طحن

دراسة عن أثر النظام التكنولوجي على أداء زجاج الرماد المتطاير الرغوية

معدات التعدين الصينية الصينية ق

شركة تصنيع اللجنيت

الكسارات المتنقلة للإيجار جنوب أفريقيا

محطم الساحرة لاستخدامها في سحق الطوب القديم

آلات ومعدات محطم الذهب

شراء آلات طحن للبيع على الإنترنت

cloncurry سنگ شکن سنگ شمال غرب DXN

5 محور الطين مصنع الصين؟ ساماتش

المنتجات فرز النفايات

لنا مزادات كسارة الصخور الصغيرة

تكنولوجيا التعدين الدولية أستراليا

حجم سوق صناعة التعدين محطم

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20